Chemical labels play a vital role in keeping workplaces safe, and different systems are designed to highlight hazards in clear ways. Two of the most widely used are GHS labels, which provide hazard information, and NFPA labels, which give quick, at-a-glance safety guidance.

Understanding the differences is important for compliance, workplace safety, and emergency preparedness.

What Are GHS Labels?

The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) was developed by the United Nations (UN) to create a universal language for chemical hazard communication. Before GHS, every country had its own system, which often caused confusion and increased risk when chemicals were imported, exported, or handled by multinational companies.

In the United States (US), GHS is implemented through OSHA’s Hazard Communication Standard (HazCom 2012). This means that every manufacturer, importer, or distributor must ensure that shipped chemical containers have GHS-compliant labels.

Required elements of a GHS label:

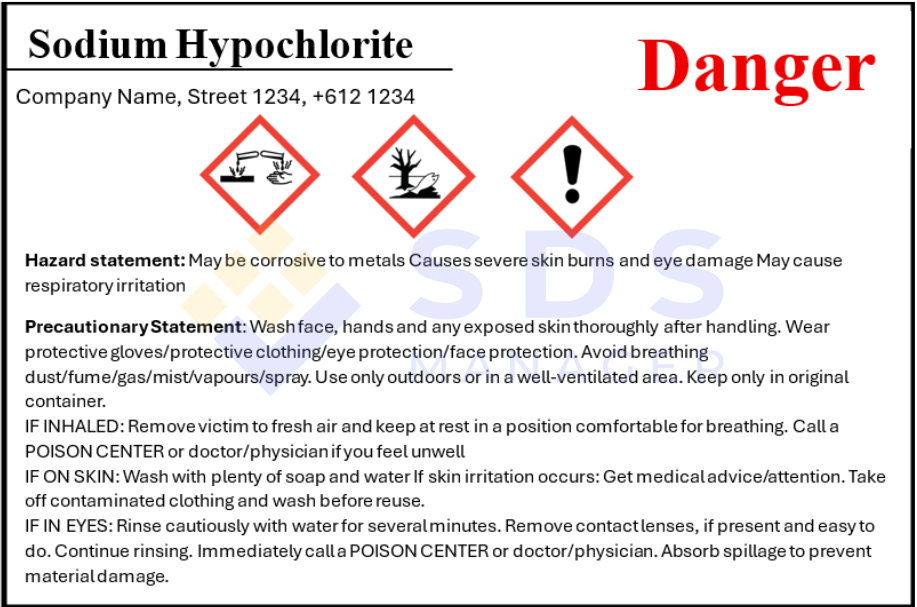

A GHS label must include the following 6 elements to communicate the potential hazards of a chemical product and provide safety guidance to users:

- Product identifier – The name or code that matches the Safety Data Sheet (SDS).

- Supplier information – Name, address, and contact details of the responsible party.

- Signal word – Either “Danger” or “Warning,” depending on the severity of the hazard.

- Hazard statements – Standardized phrases describing risks (e.g., “Causes skin irritation”).

- Precautionary statements – Instructions for safe handling, storage, PPE, and first aid.

- Pictograms – Red diamond symbols showing hazard types (e.g., flame, skull, corrosion).

- Supplemental information – As required by OSHA or international laws.

Role in the workplace:

GHS labels are designed for daily use by workers. They help employees understand how to handle chemicals safely, prevent accidents, and know what to do in case of exposure. All chemical containers including secondary containers should be labelled.

A GHS Label looks like:

What Are NFPA Labels?

The NFPA 704 system, commonly called the NFPA diamond or fire diamond, was created by the National Fire Protection Association in the US.

Unlike GHS, NFPA labels are not legally required by OSHA. Instead, they are widely used among emergency responders like firefighters, paramedics, or hazmat teams with quick hazard recognition.

The NFPA Diamond:

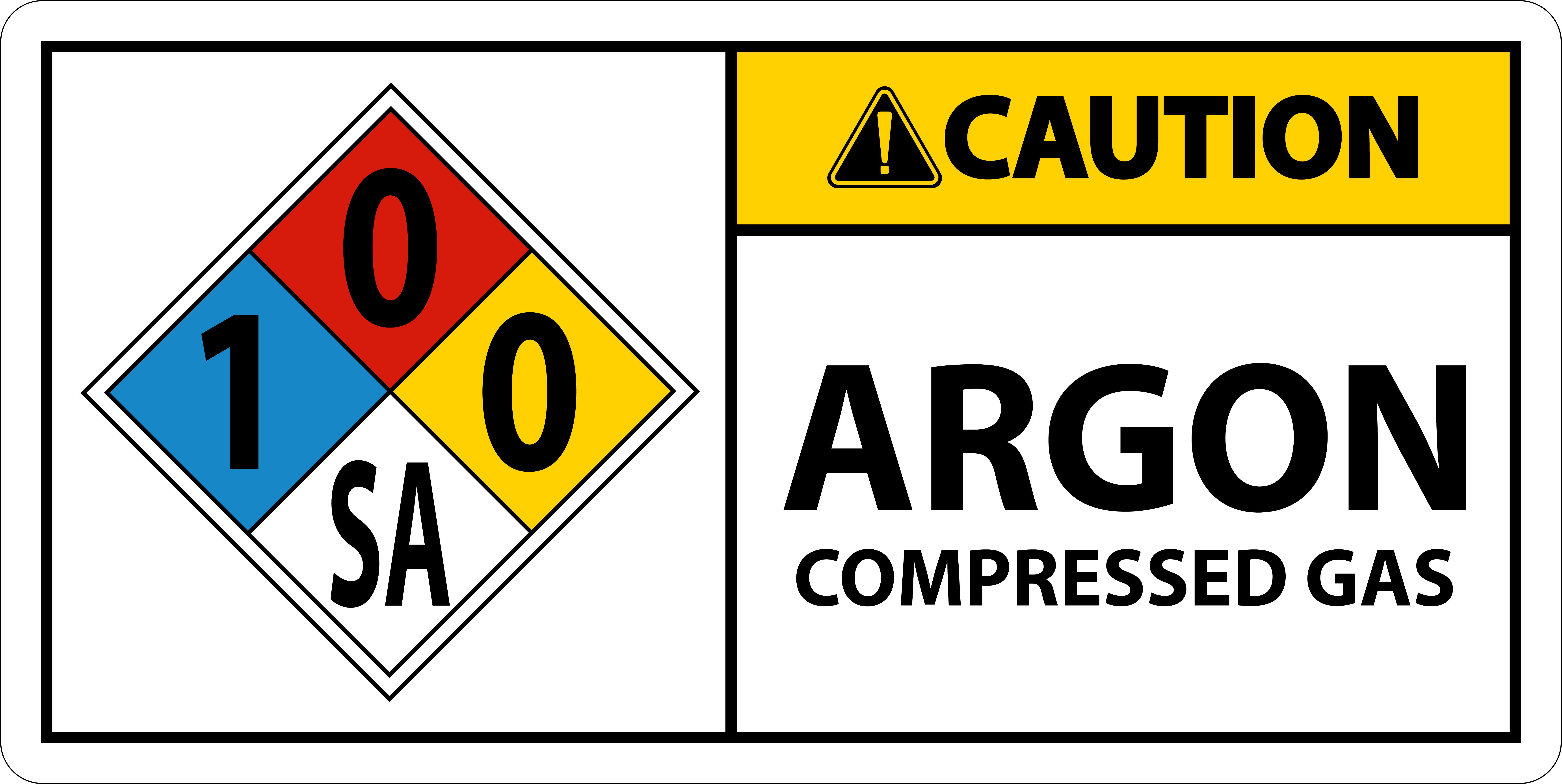

It’s divided into four colored quadrants:

- Blue (Health hazard): 0 = minimal hazard, 4 = severe hazard.

- Red (Flammability): 0 = will not burn, 4 = extremely flammable.

- Yellow (Instability/reactivity): 0 = stable, 4 = may detonate/explode.

- White (Special hazards): symbols or codes like OX (oxidizer), W (reacts with water).

Role in the workplace:

NFPA labels are simplified and intended to give emergency crews fast, actionable knowledge during a fire, spill, or explosion. While employees can benefit from understanding the NFPA diamonds, their main purpose is emergency response.

An NFPA label looks like:

Why Do We Have Two Systems?

If GHS labels are already required then what role does NFPA play?

The answer lies in their different functions:

- GHS is about comprehensive hazard communication for everyday workplace use, practiced globally.

- NFPA is about rapid hazard recognition during emergencies, highly practiced among specific workplaces in the United States.

A well-prepared workplace often uses both together. The containers are shipped with GHS labels while storage areas, tanks, and facility signage features NFPA diamonds to alert first responders

Key Differences Between GHS and NFPA Labels

| Feature | GHS Labels | NFPA Labels |

|---|---|---|

| Purpose | Detailed hazard communication for workers | Quick hazard recognition for emergency responders |

| Regulatory Status | Mandatory under OSHA HazCom 2012 | Voluntary, but widely used in the US. |

| Format | Red diamond pictograms + text | Four-colored diamond with numbers/symbols |

| Hazards Covered | Health, physical, and environmental hazards | Health, flammability, reactivity, special hazards |

| Scale/Numbers | Hazard categories (1 = most severe, 5 = least severe) | Numeric ratings (0 = minimal, 4 = most severe) |

| Audience | Workers, employers, compliance officers | Firefighters, hazmat, first responders |

One common source of confusion: GHS and NFPA scales run in opposite directions.

- GHS Category 1 = most severe hazard

- NFPA rating 4 = most severe hazard

This is why it’s critical not to assume the numbers are interchangeable.

Final Thoughts

When comparing GHS labels vs NFPA labels, it’s important to see them as complementary, not competing.

GHS labels are mandatory and provide detailed, standardized hazard information for safe handling. While NFPA labels are voluntary but extremely useful for emergency responders.

Together, they form a stronger safety net protecting employees during routine work and supporting firefighters and hazmat teams in emergencies.

For employers, the takeaway is clear. Make sure every chemical in your workplace is properly labeled with a GHS-compliant label and consider adding NFPA diamonds in storage and use areas for an added layer of safety.