Chemical safety is all about handling chemicals in a way that keeps people, property, and the environment safe from harm.

Some chemicals can catch fire, create fumes, corrode or cause allergic reactions. When handling chemicals, it is important to know how to store, use, clean or dispose of them.

This guide explains what the rules are, why they matter, and how to apply them for a safer workplace.

What chemical safety rules are, and why they matter

Different chemicals have different kinds of risks when handling them. These may include health effects like asthma or cancer and physical hazards like risk of flammability or explosion.

Chemical safety rules are a set of standard instructions on how to reduce the chances of these harmful effects from happening.

Chemical safety rules and steps to take that help create a safer workplace

Before setting the rules, it is important to be able to spot and identify what chemicals cause chemical hazards, their effects and how to prevent them. The simplest method to know the sources include:

- Reading the GHS label on the container of a substance

- Checking the Safety Data Sheet for important information such as, what not to mix with, recommended protective gear and other methods to minimize or prevent the risk

A clear rule set by NIOSH, Hierarchy of Controls, has been adopted globally as the first go-to rule for chemical safety and hazard prevention. Let us expand on what these are below.

1. Controlling or Reducing the Risk

The five steps in NIOSH’s Hierarchy of Controls are as follows:

Eliminate:

If the process can be done, removing the hazardous chemical from the picture, it removes the hazards from the picture.

Example: Use scrubbing brushes or steam cleaning instead of using chemical cleaning agents.

Substitute:

Consider using a safer replacement or a weaker concentration.

Example: Using a different formula for a product that would remove the use of a toxic chemical for a safer one.

Engineering Controls:

If substitutes are not available, then you can create control methods to separate people from the hazard source.

Example: Using fume hoods help workers handle the chemicals within a closed-off space, preventing the inhaling of toxic fumes.

Administrative Controls:

This includes training workers, assigning clear labels and other work practices that reduce how often, how long, or how much hazards affect workers.

Example: Rotate workers to reduce extended exposure.

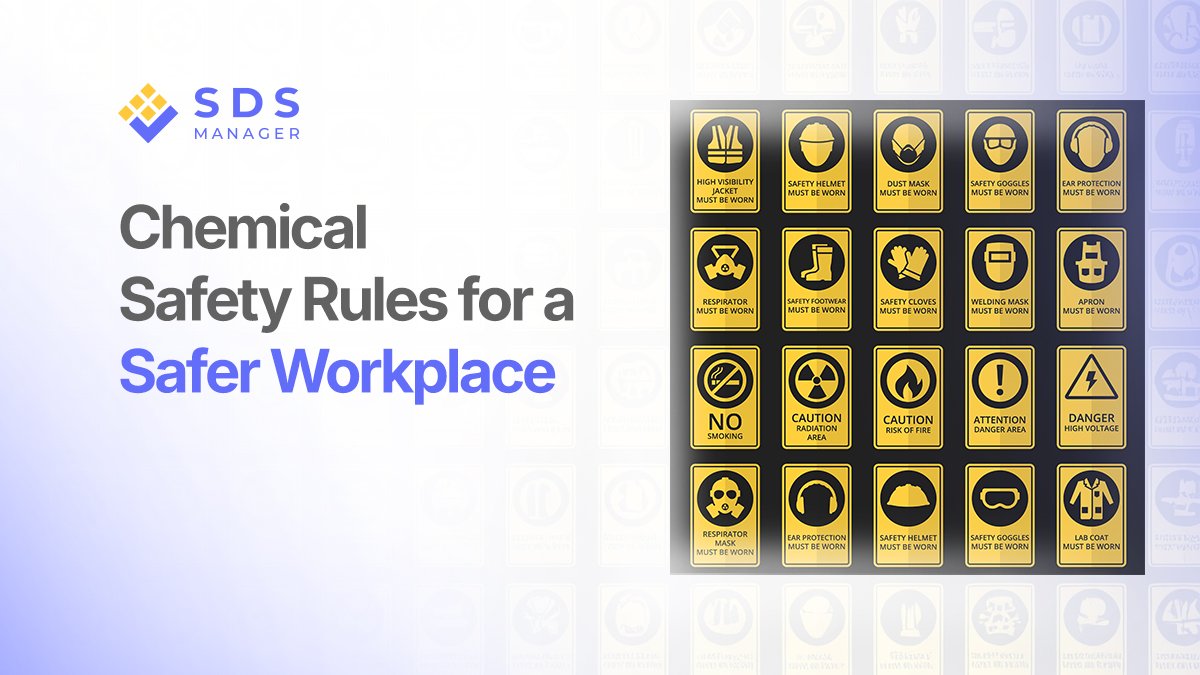

PPE:

Finally, use the right protective gear for tasks, based on the route of exposure.

Example: Use goggles or face shields to protect against face or eye exposure, or gloves when handling chemicals that can be corrosive. The correct equipment type for handling each chemical can be learned about from an SDS.

2. Storing and Handling by compatibility

Some chemicals may react or create hazards if stored together. In such cases, it is important to store them separately.

- Acids should be kept separate from bases

- Oxidisers should be stored away from organic materials, which have a risk of combustion

- Keep materials such as alkali metals that can violently react with water, away from any water sources

Secondary container labels should include the product name, hazard (H) pictograms and H and Precautionary (P) statements, and manufacturer name and contact.

3. Set effective Waste-management and Cleanup

Similarly to storage and handling, chemicals should be disposed of separately.

- Label and Seal: Always put a label on chemical waste containers and make sure the lids are on tight.

- Don't Mix: Never pour different types of chemical waste into the same container.

- Keep Paths Clear: Make sure nothing is blocking exits or access to emergency equipment like fire extinguishers or eyewash stations.

- Clean & Report: Wipe down your work area at the end of your shift and be sure to report any safety issues you noticed.

These simple habits go a long way in preventing spills, accidents, and keeping everyone safe on the job.

How strong chemical rules improve safety and operations

Effective chemical safety protects workers and reduces operational risk. Regardless of the nature of your workplace - from labs, to hospitals, to chemical manufacturing plants - simple rules that everyone can follow should be part of your safety routine.

When safety data sheets are easy to find, procedures are clear, chemicals are stored correctly, and spill response is practiced, you get fewer accidents and keep workers safe.

FAQs

What’s the first step to improve chemical safety?

Build a current chemical inventory, make sure the right SDS are accessible, and train by task using those details.

Do secondary containers need labels?

Yes. Use workplace labels with key GHS elements so workers can see the hazards at a glance.

When is exposure monitoring needed?

If tasks or SDS indicate inhalation risk, check the air against limits and improve controls based on what you find.

Is PPE enough on its own?

No. Prioritize ventilation and other engineering controls, then use PPE as the last line of defense.

Which operations trigger extra requirements?

Processes with certain highly hazardous chemicals may fall under OSHA Process Safety Management, which adds equipment inspection and maintenance requirements, detailed procedures, and training.