PFAS (polyfluoroalkyl or perfluoroalkyl substances) are often referred to as “forever chemicals” because their chemical bonds are extremely strong, making them highly resistant to breaking down in the environment or in the human body. As bioaccumulative substances, they can build up over time in soil, water, wildlife, and human tissue, resulting in long-term exposure even at low concentrations. Because they persist for years and do not easily degrade once released, regulators are paying closer attention to how these chemicals are classified, reported, and disclosed in Safety Data Sheets.

Federal oversight of PFAS, is increasing, and the impact now goes beyond environmental discharge rules. Updated guidance and enforcement signals from the Occupational Safety and Health Administration and the Environmental Protection Agency are changing how employers review chemical documentation, especially Safety Data Sheets.

Not every update creates a new binding rule, but the overall message is clear. Regulators expect documentation to reflect updated toxicology findings, expanded reporting requirements, and clearer hazard communication.

For employers that manufacture, distribute, or use PFAS containing materials, these guidance updates are becoming practical compliance standards.

Using a digital SDS solution to quickly update hazard classifications, maintain current regulatory listings, and distribute the latest safety information to employees and downstream users.

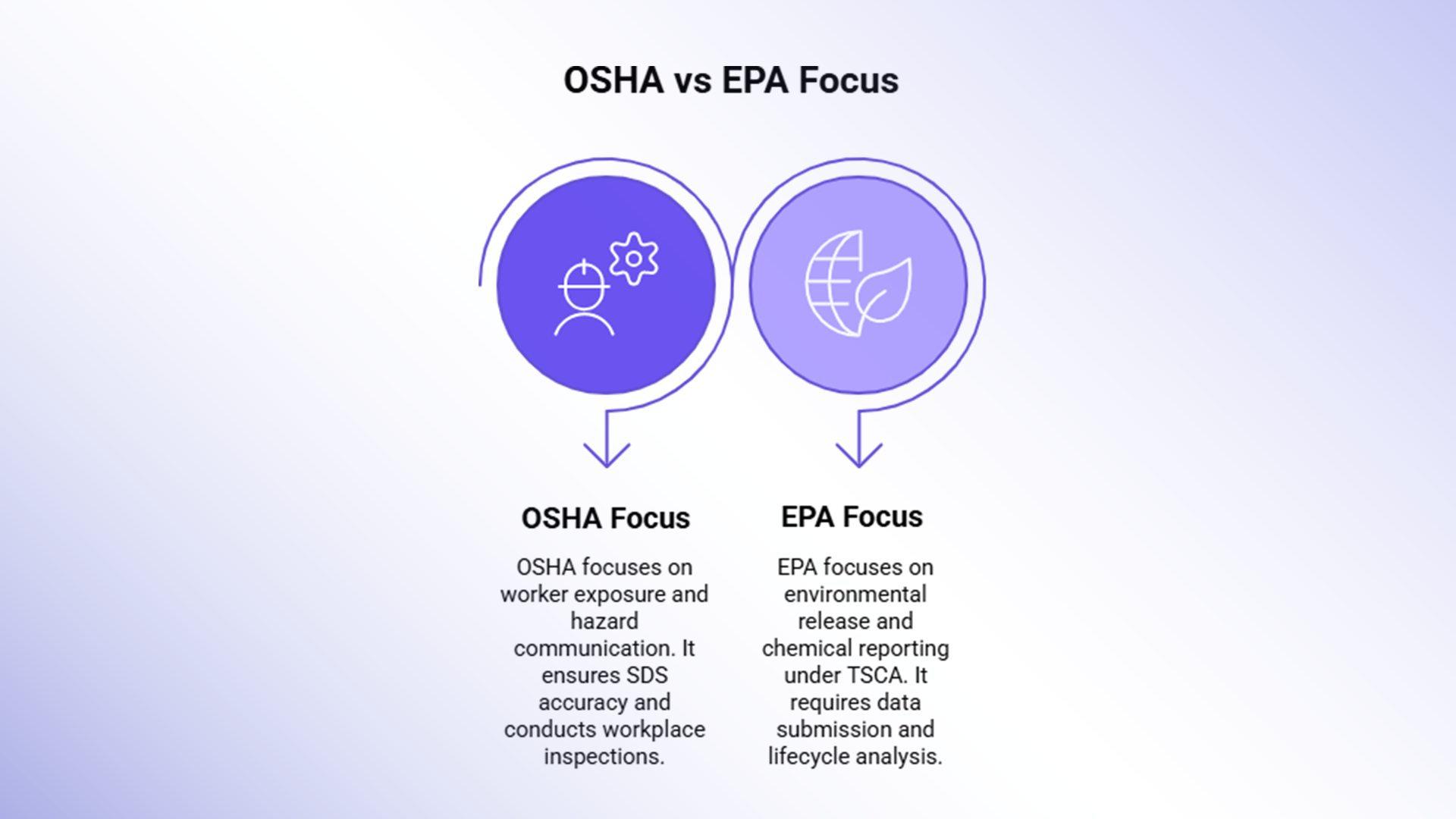

How Environmental Rules Impact Workplace Compliance

Historically, PFAS regulation has been driven largely by environmental concerns like water contamination, waste disposal, and long-term ecological impact. That focus is now intersecting directly with workplace safety obligations.

EPA updates under the Toxic Substances Control Act (TSCA) are expanding reporting requirements, while OSHA is paying closer attention to hazard communication and inspections.

Because of this, any gaps between environmental reports and SDS hazard information are more likely to draw regulatory scrutiny.

PFAS exposure is not only an environmental concern but also an occupational one. A 2025 study of nearly 2,000 U.S. workers found that firefighters had the highest blood concentrations of several PFAS compounds, while healthcare workers also showed elevated levels compared to other professions. The findings underscore the importance of clear hazard communication and up-to-date Safety Data Sheets in workplaces handling PFAS. (Arizona Health Sciences, 2025)

How We can Stay Compliant with the New Regulatory Update

The recent OSHA and EPA updates show that regulators are paying closer attention to how PFAS hazards are documented and communicated. The updates also signal that supply chain transparency is increasingly important. Companies must track PFAS-containing products, update documentation quickly, and make sure employees and downstream users have access to the latest Safety Data Sheets.

To translate these guidance updates into practical steps, employers should focus on three key areas of SDS compliance: hazard classification, regulatory listings, and document management.

1. Hazard Classification Is Under Review

As toxicological evidence evolves, PFAS substances may require re-evaluation under hazard classification criteria. Chronic exposure concerns, bioaccumulation characteristics, and potential carcinogenic effects are receiving heightened scrutiny.

SDS Section 2 (Hazard Identification) must reflect current interpretations of available data. Regulators increasingly view outdated classifications as a red flag during inspections.

2. Regulatory Listings Must Be Current

Section 15 (Regulatory Information) is becoming a focal point. With expanding federal and state PFAS rulemaking activity, static or outdated references can quickly create compliance gaps.

Guidance updates reinforce the expectation that SDS regulatory citations align with current federal reporting obligations and applicable restrictions.

3. Distribution and Version Control Matter More Than Ever

Expanded EPA reporting emphasizes traceability across supply chains. Employers must demonstrate:

- Clear version control

- Timely SDS updates

- Accessible documentation for employees

- Prompt downstream distribution

Manual systems may struggle to keep pace as revision cycles accelerate.

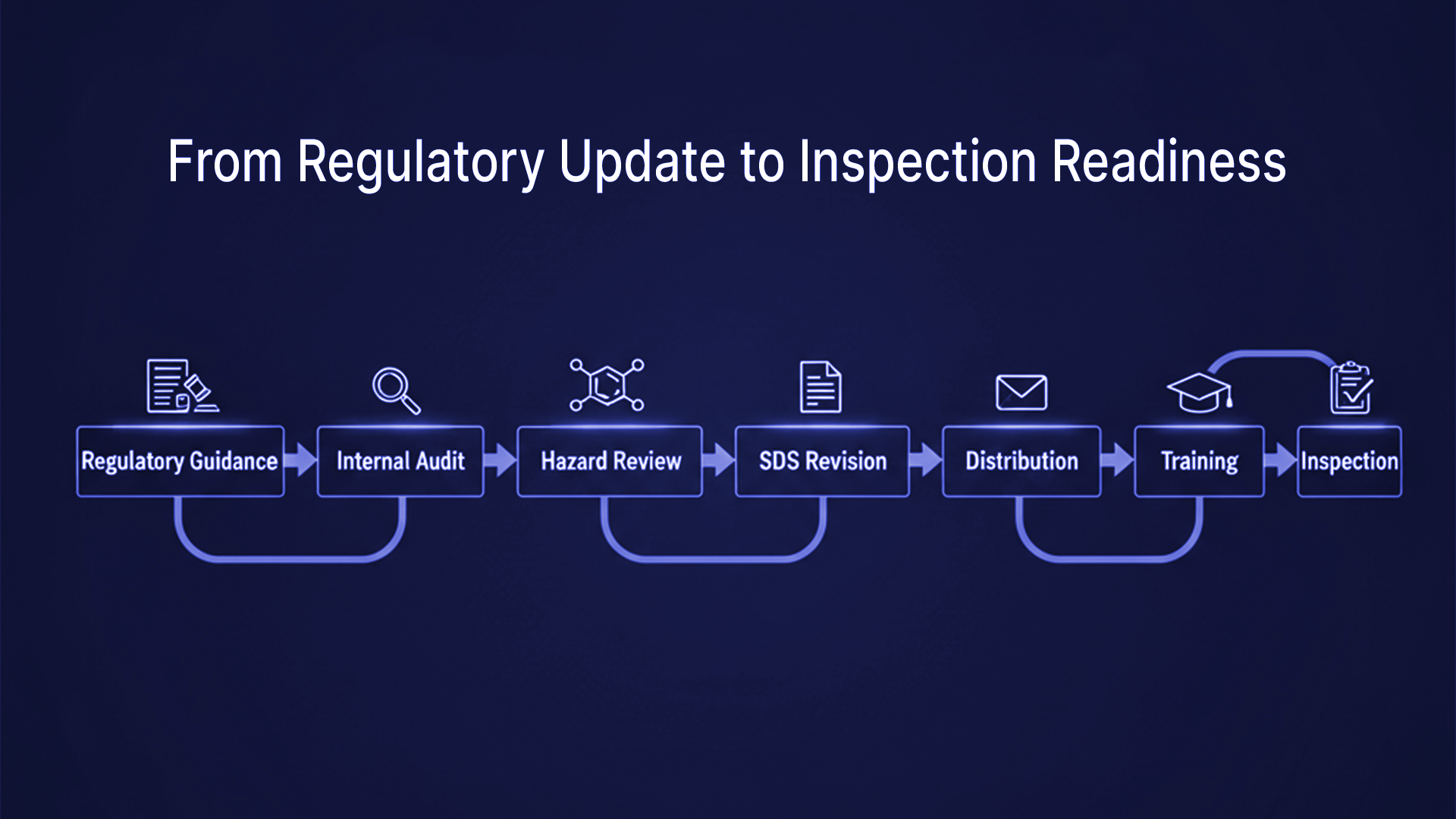

The Process of Updating SDSs After Regulatory Changes

Regulatory updates rarely impact just one department. They initiate a compliance chain reaction.

When EPA revises reporting expectations or OSHA reinforces hazard communication standards, employers should move through a structured internal process:

- Review updated guidance and enforcement signals.

- Assess product inventory for PFAS content.

- Reevaluate hazard classifications.

- Update SDS sections where required.

- Distribute revised SDSs internally and externally.

- Train employees on any new hazard disclosures.

Organizations that formalize this process reduce inspection risk and demonstrate proactive compliance management.

Why 2026 Is a Turning Point

PFAS oversight is transitioning from exploratory data collection to structured regulatory action. Federal agencies are signaling that transparency and documentation accuracy are now central to enforcement strategy.

Even in the absence of a PFAS-specific OSHA standard, Hazard Communication requirements already provide a mechanism for inspection citations if SDSs fail to reflect current hazard knowledge.

For employers, waiting for formal rulemaking may result in documentation lagging behind regulatory expectations.

Across the country, PFAS contamination has triggered a growing number of lawsuits. Tens of thousands of individuals and communities have pursued claims against manufacturers over contaminated water supplies, with many cases consolidated in federal courts. The legal landscape reflects the increasing urgency for companies to maintain accurate chemical documentation and SDS compliance. (Robert King Law Firm, 2025)

In short, regulatory guidance is something to act on, not just read.