The Globally Harmonized System (GHS) continues to influence chemical safety regulations worldwide. In the United Kingdom, post-Brexit regulatory frameworks have adapted GHS principles into domestic law, directly impacting the requirements for Safety Data Sheets (SDS) in 2025.

Understanding the UK’s Regulatory Landscape

Following the UK's departure from the EU, the country established its own version of the Classification, Labelling and Packaging (CLP) Regulation, commonly referred to as GB CLP. This regulation is closely aligned with GHS standards and is enforced by the Health and Safety Executive (HSE). The UK REACH Regulation also governs the safe supply, handling, and use of chemicals, with specific requirements for SDS.

Key GHS-Driven Changes to SDS Requirements

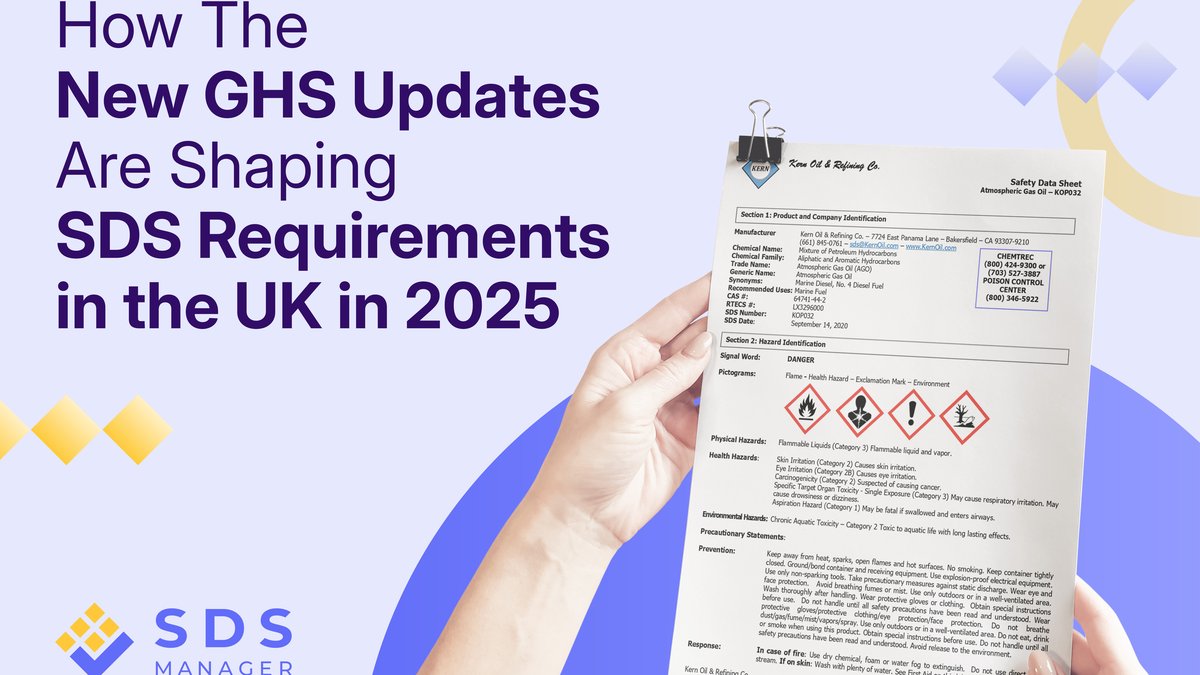

- Alignment with GHS Principles: The UK’s SDS requirements are structured to reflect the latest GHS updates, ensuring that hazard classification, labelling, and communication remain consistent with international best practices. [See here]

- Comprehensive Hazard Communication: SDS must present clear information on hazards, including hazard statements, precautionary statements, and relevant pictograms. This ensures that users understand the risks and necessary precautions when handling chemicals. [See here]

- Risk Assessment Support: The information within the SDS is critical for employers to conduct risk assessments as mandated by the Control of Substances Hazardous to Health Regulations (COSHH). While the SDS itself is not a risk assessment, it provides the necessary details to support one.

- Applicability: An SDS is required for any hazardous chemical supplied for workplace use, regardless of packaging. Even non-hazardous chemicals require an SDS if they contain small amounts of hazardous substances.

Recent and Upcoming Developments in 2025

- Continued Updates: The UK government regularly reviews and updates SDS requirements to stay in line with evolving GHS revisions. Businesses must ensure their SDS reflect the latest hazard classifications and labelling protocols as outlined by HSE and UK REACH.

- Notification Obligations: Companies introducing new substances to the GB market must notify the HSE within one month, ensuring that all SDS information is current and compliant with GB CLP requirements. [See here]

- Transport and Packaging: For those transporting dangerous goods, strict rules apply to packing and labelling, closely linked to the information provided in SDS.

Practical Implications for Businesses

- Ongoing Compliance: Companies supplying chemicals in the UK must regularly review and update their SDS to reflect the latest GHS and GB CLP changes.

- Training and Communication: Employers should ensure that all staff handling chemicals are familiar with the updated SDS and understand the hazard information and recommended precautions.

- Support and Guidance: The HSE provides detailed guidance on compiling SDS and offers a helpdesk for specific queries related to UK REACH and SDS requirements.

In 2025, GHS updates continue to shape the content and structure of Safety Data Sheets in the UK. By aligning with international standards and maintaining a robust regulatory framework, the UK ensures that chemical hazards are communicated effectively, supporting workplace safety and environmental protection. For the most current guidance, businesses should consult the HSE and UK government resources.

How SDS Manager Can Help

Navigating these complex and dynamic SDS requirements demands robust SDS management solutions. SDS Manager offers a comprehensive platform designed to keep your chemical safety program aligned with the latest GHS standards and UK laws.

Key Features That Help You Stay Compliant:

- Extensive safety data sheet Database & Import Tools: Access more than 16 million SDSs and easily import your chemical inventory to build a complete, up-to-date safety data sheet library.

- Automated safety data sheet Updates: Receive timely notifications for safety data sheet revisions and updates, ensuring your data reflects the latest hazard information.

- One-Click Access to Safety Information: Instantly access hazard details, PPE icons, first aid instructions, and spill precautions. Generate Safety Information Summaries for employee guidance.

- Secondary Container Label Generation: Create compliant labels in multiple sizes featuring QR codes, hazard codes, and PPE icons to meet labeling requirements.

- QR Code Integration & Mobile Access: Generate QR codes and posters for instant safety data sheet access on mobile devices, improving hazard communication and worker safety.

- Compliance Reporting: Generate detailed reports to stay audit-ready and demonstrate regulatory compliance effortlessly.

Getting Started Is Easy

Here's how you can take the next step toward streamlined chemical safety and compliance:

- Contact Us For Free Setup Support

- Uncover Features Designed With Your Challenges In Mind

- Book A 1:1 Consultation To Discuss Unique Compliance Needs

Take the First Step Toward Smarter SDS Management: Start Your Free Trial Today!