Managing facility safety is a heavy responsibility. Every year, thousands of workplace fires put lives at risk and cause significant damage.

Fortunately, most of these incidents are preventable. Real fire safety in the workplace goes beyond just hanging a few exit signs.

It means knowing your specific risks and ensuring the team can react without panic. This guide covers the necessary steps to keep your workplace protected.

Identifying Common Hazards to Improve Fire Safety in the Workplace

If you want to stop fires, you have to know where they start. You might expect industrial machinery to be the main culprit, but standard office environments pose surprisingly high risks.

In the UK, faulty appliances and leads are a leading cause of non-domestic fires. We are talking about simple things like overloaded extension leads, frayed wires, or that portable heater under a desk.

Misuse of equipment isn't far behind. Using a toaster oven improperly in the breakroom or obstructing equipment ventilation is often more dangerous than heavy machinery.

If you manage a warehouse or storage facility, focus on combustible storage like cardboard or chemicals. These are fuel waiting for a spark, especially given the risks of arson in commercial areas.

Keep an eye out for warning signs like warm sockets, flickering lights, or burning smells. Now that you know what to watch for, let's focus on building a program that works.

Building a Strategy for Fire Safety in the Workplace

Prevention beats emergency response every time, but you need both working together. Here is how to build a complete fire safety program.

Conducting Comprehensive Fire Risk Assessments

Under the Regulatory Reform (Fire Safety) Order 2005, you must appoint a 'Responsible Person' to conduct a risk assessment.

Start by walking through your facility to identify fire sources. Specifically, check electrical equipment, heating systems, hot work (welding/cutting) areas, and chemical storage locations.

Write down your findings and create action plans to address each problem. This sets up accountability and ensures hazards don't get overlooked.

Be sure to update these assessments regularly. Do this whenever you add new equipment, change layouts, or modify operations.

Putting Good Housekeeping and Maintenance in Place

Good housekeeping is your passive defense against fire. It starts with the basics, such as keeping walkways and exit routes completely clear of clutter.

But you also need to look at invisible risks. In offices, this means regular waste disposal. In manufacturing, it implies strict schedules to control combustible dust.

Ensure your safety systems are ready to work. Check fire extinguishers monthly and get them professionally serviced annually to British Standards (BS 5306).

You must also test your fire alarm system weekly using different call points. This strict testing schedule ensures the system never fails when needed.

Training Your Team for Emergency Response

Even the best plan falls apart if your people panic. That is why training is less about compliance and more about muscle memory.

The law requires adequate safety training when staff are inducted and periodically thereafter. To make it stick, you need hands-on practice.

When an employee physically holds an extinguisher or walks the evacuation route, their confidence doubles. They stop thinking about what the manual said and just act.

Learning Fire Extinguisher Basics

UK extinguishers use a color-coded band system to denote their type (Water, Foam, Dry Powder, CO2, or Wet Chemical). Ensure staff know which to use.

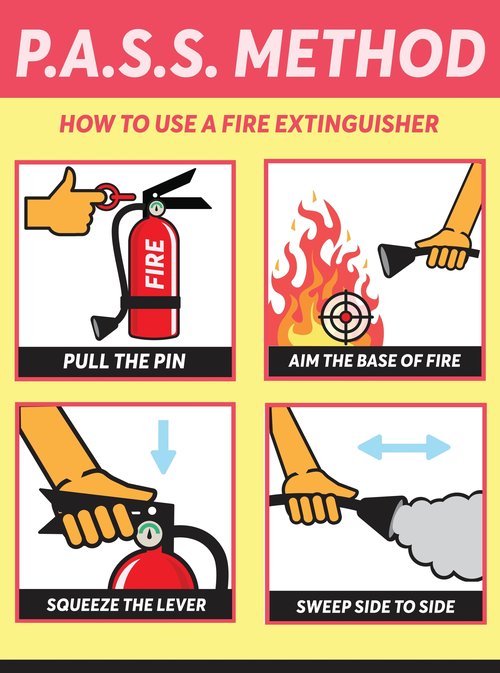

However, the operation usually follows the PASS technique:

- Pull the safety pin.

- Aim at the base of the fire.

- Squeeze the handle.

- Sweep side to side.

Remember that extinguishers work only for small, contained fires. If flames reach the ceiling or smoke fills the room, evacuate immediately.

Running Regular Fire Drills

You should carry out a fire drill at least once a year and record the results. Facilities with higher risks may need more frequent drills.

Regular training improves response times significantly. After each drill, sit down with your team to evaluate performance.

Identify what worked and where confusion happened. This feedback loop is the difference between a safe evacuation and a tragedy.

Creating a Comprehensive Emergency Action Plan

Even with strong prevention measures, you need a solid plan for when fire strikes. Clear procedures save lives by removing confusion and making evacuations swift.

Designing Clear Evacuation Routes and Procedures

You must clearly mark evacuation routes throughout your facility using standard green "running man" signs. All exits need illuminated signs visible even in smoke.

It is also critical to post evacuation maps showing these locations throughout the building. This ensures information is always accessible.

Always plan for redundancy. Having multiple exit options gives employees backup escape routes if primary paths get blocked.

Assign specific people to maintain these pathways. You must ensure they never become storage areas.

Establishing Assembly Points and Fire Marshals

Pick specific outdoor locations where employees gather after evacuating. These assembly points need to be at a safe distance, well away from falling glass or heat.

You should also designate Fire Marshals (or wardens) who understand emergency procedures. Organizations with larger staff numbers typically need multiple marshals.

These leaders get specialized training in evacuation procedures. They are responsible for checking spaces before exiting and tracking personnel.

Final Thoughts

Fire safety requires ongoing commitment, but getting started is straightforward. Begin by checking your facility for hazards and identifying risks.

Next, create or update your emergency action plan. Set up evacuation routes, assign clear responsibilities, and put regular training in place.

The preparations you make today could save lives tomorrow.

Frequently Asked Questions

What are the primary causes of UK workplace fires?

Faulty appliances and leads are a top cause, along with misuse of equipment and arson. Regular PAT testing (Portable Appliance Testing) and proper security can prevent most incidents.

How frequently should workplaces conduct fire drills?

You must conduct a fire drill at least once a year. However, high-risk environments or schools often conduct them once a term or every six months.

Who bears responsibility for workplace fire safety?

The designated "Responsible Person" holds legal responsibility under the Regulatory Reform (Fire Safety) Order 2005. They must ensure risk assessments and safety measures are in place.

What should a workplace fire evacuation plan include?

Your plan needs evacuation routes, assembly points, Fire Marshal assignments, and plans for vulnerable staff (PEEPs - Personal Emergency Evacuation Plans). You should also post clear evacuation maps.