A Safety Data Sheet (SDS) is essential for communicating chemical hazards to workers. Outdated or inaccurate SDSs can result in inappropriate handling, increased risk of injury, and non-compliance with national Work Health & Safety (WHS) regulations.

Keeping your SDS library current is both a legal requirement and supports safer, more informed decision-making across your operations.

Regulatory Requirements at a Glance

| Jurisdiction | Update Deadline | Relevant Rule / Standard |

|---|---|---|

| Health and Safety at Work (Hazardous Substances) Regulations 2017 | SDS must be reviewed and reissued at least every 5 years, or immediately when new significant information becomes available | Regulation 2.3, Schedule 8: Requirements for safety data sheets |

| WorkSafe NZ | Requires suppliers to ensure SDSs reflect current knowledge of chemical risks and are available to downstream users | Hazardous Substances Toolbox and HSW Regulations guidance |

| Employer Responsibilities | SDS must be accessible at the workplace and match the most recent version from the supplier | Part 4, Regulation 2.2: Duties of PCBU handling hazardous substances |

Key Triggers That Demand an Update

Even though Australia mandates a 5-year review cycle, SDS must be updated earlier if any of the following apply:

- New Information Arises

Updated toxicological data, physical hazards, or environmental risks. - Changes in Formulation

Any change in composition, concentration, or supplier that alters the product's hazard profile. - Supplier Notification

If your supplier revises the SDS, employers are required to replace the old version immediately. - Improved Control Measures

Introduction of new risk controls or changes to existing ones that impact safe handling recommendations. - Regulatory Amendments

Updates to classifications under the GHS or national guidance may trigger SDS updates.

Recommended Review Cycles & Best Practices

While WHS legislation mandates reviews every five years, proactive companies apply more frequent internal checks:

| Review type | Frequency / trigger | What to do | Recordkeeping tip | Why it matters |

|---|---|---|---|---|

| Quarterly Update Monitoring | Every quarter | Monitor supplier websites and WorkSafe bulletins for reclassification or new control measures; flag impacted SDS. | Keep a simple change log by product/CAS and link sources. | Catches changes early; reduces compliance risk. |

| Annual Checks | Once per year | Scan your SDS library for sheets nearing expiry; request and replace with current supplier versions. | Maintain an SDS register with version/expiry and confirmations. | Keeps documents current and audit-ready. |

| After Any Safety Incidents | Immediately after any spill, exposure, or near-miss | Review the relevant SDS for accuracy and clarity; update SOPs, training, and signage as needed. | Record the review and corrective actions in the incident report. | Improves response and prevents recurrence. |

These checks ensure you're not relying solely on the 5-year window and stay compliant in dynamic environments.

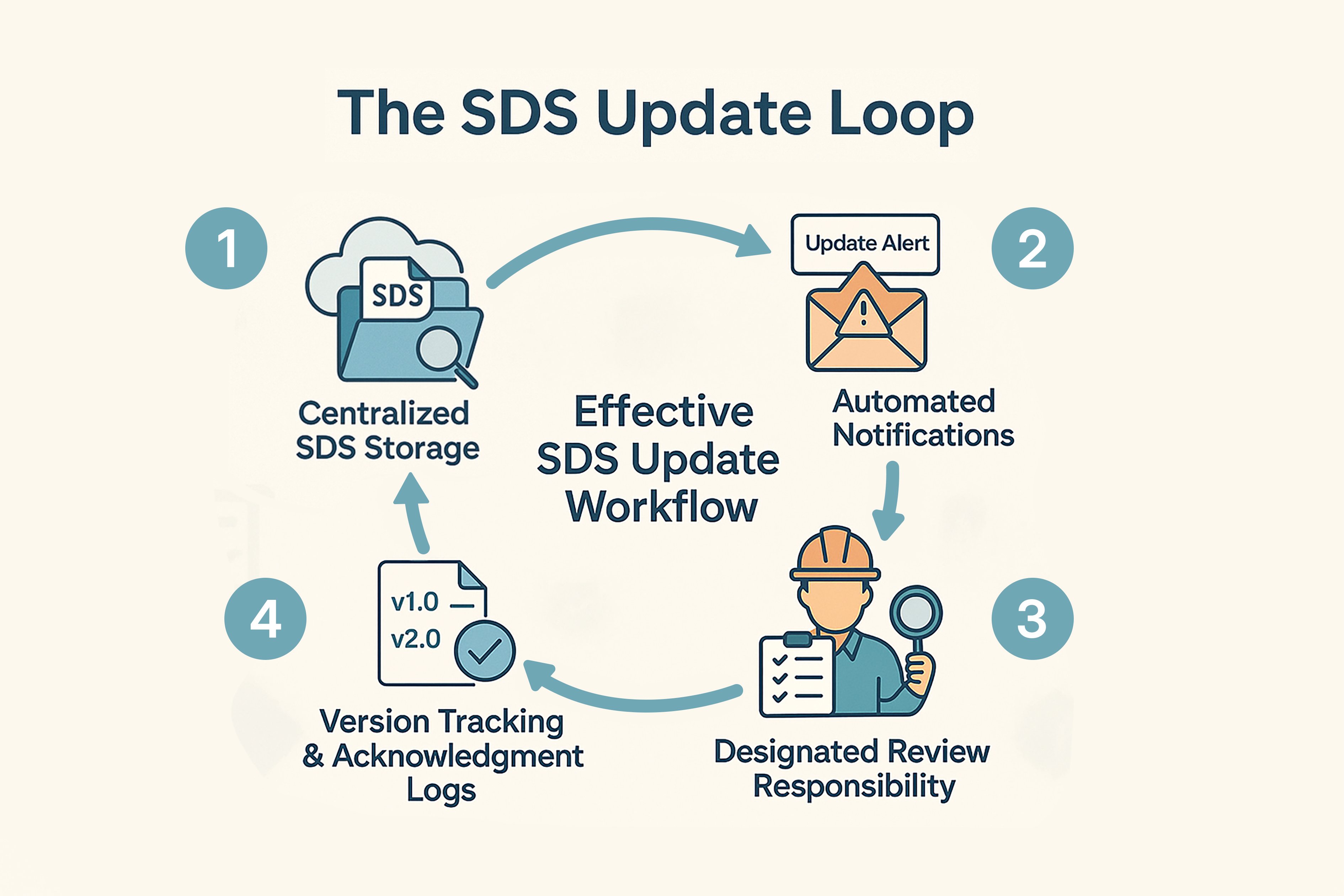

Building an Effective SDS Update Workflow

A consistent approach to SDS management strengthens both compliance and safety culture:

1. Store documents in a shared, searchable location accessible to all staff.

2. Use calendar tools or safety software to flag upcoming SDS renewals.

3. Nominate a WHS representative to own SDS maintenance tasks.

4. Maintain access logs and keep archived versions to show update history.

Staying Ahead of Future Compliance Changes

Australia’s alignment with the GHS continues to evolve, with periodic updates reflecting global changes in hazard classification. Monitoring publications from Safe Work Australia and state/territory regulators will help you anticipate revisions before the five-year review. Internally, maintaining documentation that shows when updates were reviewed, who approved them, and how they were distributed will reduce audit risk and improve workplace safety transparency.

FAQs

- How often must SDS be updated in Australia?

Every five years at minimum, or earlier if significant new hazard information becomes available. - What happens if an SDS is outdated?

Employers may be found non-compliant under WHS laws, especially if the outdated SDS contributes to a workplace incident. - Can I use a digital SDS system?

Yes. Digital formats are acceptable if they are accessible without delay and backed up. - Who is responsible for updating SDS?

Suppliers must issue revised SDSs. Employers must ensure current versions are available to workers. - Is the 5-year rule strict?

Yes, but it's a maximum. SDS must be updated sooner if hazards change, even within the 5-year period.