GHS labeling refers to the standardised way of labeling chemical containers under the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). This system was developed by the United Nations to ensure that chemical hazards are clearly and consistently communicated worldwide.

GHS labels convey the type and severity of chemical hazards, making them easily recognisable across all workplaces. The goal is to help users quickly understand the risks of a chemical and take proper precautions.

What Does a GHS Label Include?

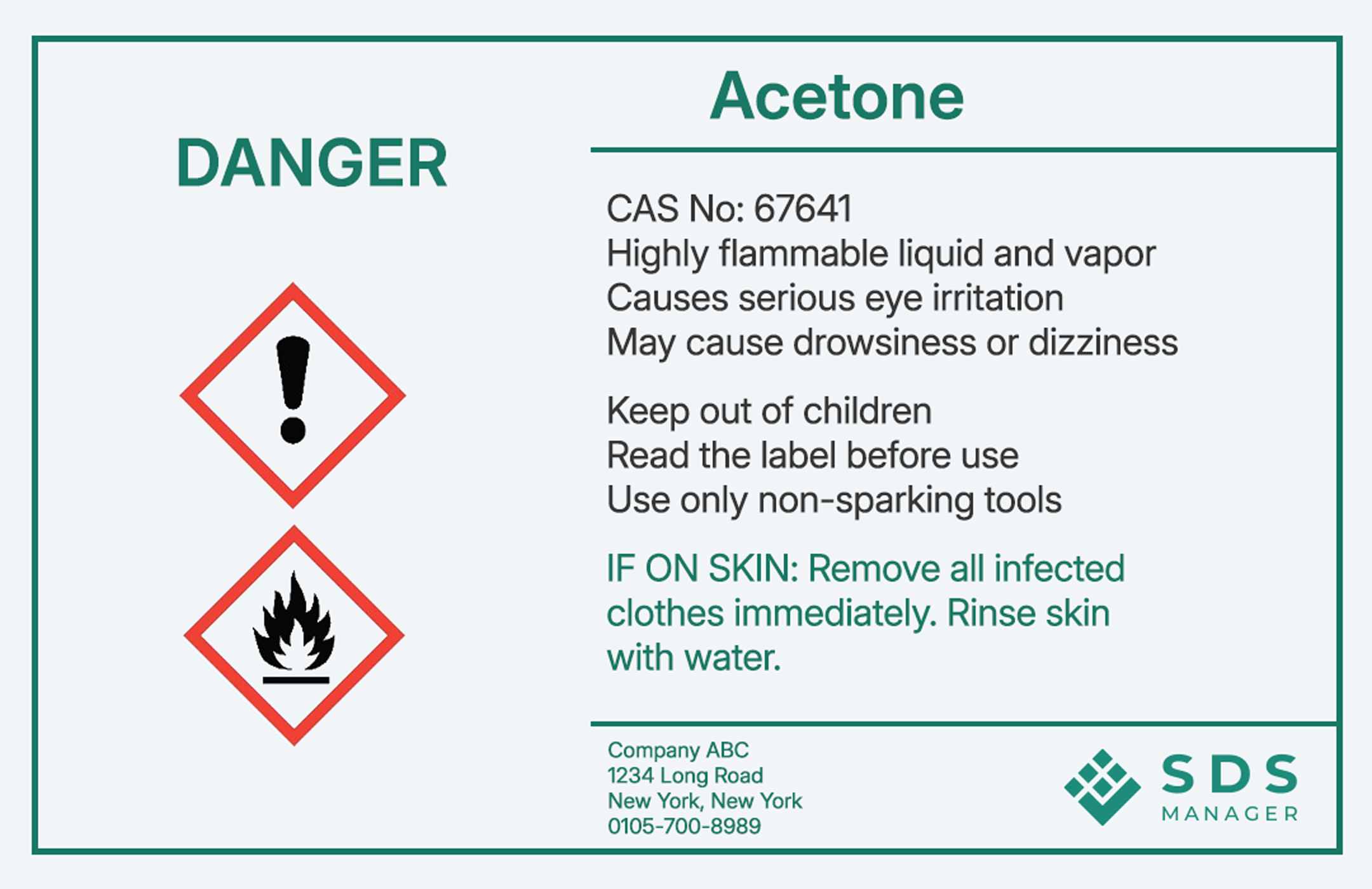

A compliant GHS label typically contains the following 6 elements:

- Product Identifier - The name or number used for a chemical.

- Pictograms – Visual icons that represent the type of hazard (e.g., flame for flammability, skull for toxicity).

- Signal Words – Either “Danger” or “Warning” to indicate severity.

- Hazard Statements – Standardised descriptions of chemical risks (e.g., “Causes skin irritation”).

- Precautionary Statements – Guidance on storage, handling, and first aid.

- Supplier Information – Name, address, and contact details of the manufacturer or distributor.

Each of these elements works together to ensure that no one handles a substance without being fully informed of the risks.

One of the most noticeable parts of GHS labeling is the pictogram, a visual symbol that quickly communicates the type of hazard a chemical presents. Each pictogram is placed inside a red diamond and represents a specific class of hazard, such as flammability, toxicity, or environmental harm.

Here are the nine GHS pictograms and what they mean:

Why Is GHS Labeling Important?

Before GHS, chemical labels varied drastically between countries and even between manufacturers leading to confusion, misinterpretation, and serious accidents. The GHS solves this by offering a globally harmonized system where the same chemical carries the same label format and hazard warnings improving communication across languages and borders.

This consistency protects workers, enhances compliance, and streamlines international trade. Chemical mishandling is one of the top causes of workplace injuries and health hazards. GHS labeling plays a major role in:

- Protecting worker health and safety

- Preventing chemical accidents and spills

- Guaranteeing compliance with international and national regulations such as the Environmental Protection Authority (EPA) in New Zealand.

- Providing clear, easy-to-understand warnings even for non specialists

The Connection Between GHS labels and Secondary Container Labels

GHS compliance does not stop with the original manufacturer’s container. When hazardous chemicals are transferred to secondary containers such as spray bottles, squeeze tubes, or smaller jars, those containers must also be properly labeled in line with GHS standards.

Under both GHS and Work Safe New Zealand’s Health and Safety at Work (Hazardous Substances) Regulations, any container used in the workplace that holds a hazardous substance must clearly display vital safety information. This includes the product name, appropriate hazard pictograms, a signal word like “Warning” or “Danger,” and basic precautionary details. The goal is to ensure that anyone handling or encountering the container understands what is inside and how to stay safe.

SDS Manager offers a free secondary container label generator tool that makes it quick and simple to create and print GHS-compliant labels. It supports all standard label sizes, including Dymo, Avery and Brady label sheets.

Who Needs GHS Labels?

GHS labeling applies to anyone involved in the production, handling, transportation, or use of hazardous chemicals, including:

- Manufacturers and importers

- Chemical suppliers and distributors

- Employers who store or use chemicals in the workplace

- Safety officers and EHS professionals

- HR and training teams responsible for onboarding employees

Even general employees who might not handle chemicals directly still benefit from understanding these labels, it’s part of maintaining a culture of safety.

GHS vs SDS: what's the difference?

GHS labels and Safety Data Sheets (SDSs) are both key components of the Globally Harmonized System, working together to ensure comprehensive hazard communication. Importantly, the information shown on a GHS label is derived directly from the corresponding SDS of a chemical, especially the hazard identification.

Here’s how they complement each other:

- GHS labels offer at-a-glance hazard information for quick understanding.

- SDSs provide in-depth data, including physical properties, first-aid procedures, storage recommendations, and regulatory information.

The GHS label gives you a quick snapshot of a chemical’s hazards, while the Safety Data Sheet (SDS) provides the full details on how to handle it safely. Together, they make sure that everyone, whether you're using, storing, or disposing of the chemical knows exactly what to do.

Final Thoughts

Understanding GHS labeling isn’t just a box to tick, it’s a foundational part of workplace safety. When employees can quickly recognize hazards and know how to respond, accidents are reduced and confidence increases.

At its core, the GHS serves as a framework to ensure that individuals working with chemicals are properly informed while labeling plays a vital role in delivering that information clearly and effectively.

If your organization handles chemicals, make sure your team is trained on how to read and apply GHS labels correctly. Managing GHS labels and SDSs doesn’t have to be overwhelming. SDS Manager helps you stay compliant, organized, and audit-ready without the stress.