Chemical safety depends on three habits: know the hazards, control exposure, and be ready for incidents.

In day-to-day lab work, that means reading the SDS, using effective ventilation (like fume hoods/LEV), choosing the right PPE, keeping benches uncluttered, and acting fast if something goes wrong.

In this article, we will walk you through the necessary safety steps aligned with global laws such as GHS (labels and SDS), and effective PPE usage to keep your laboratory safe.

Lab safety rules that must be followed for safety

1) Plan the task before handling chemicals

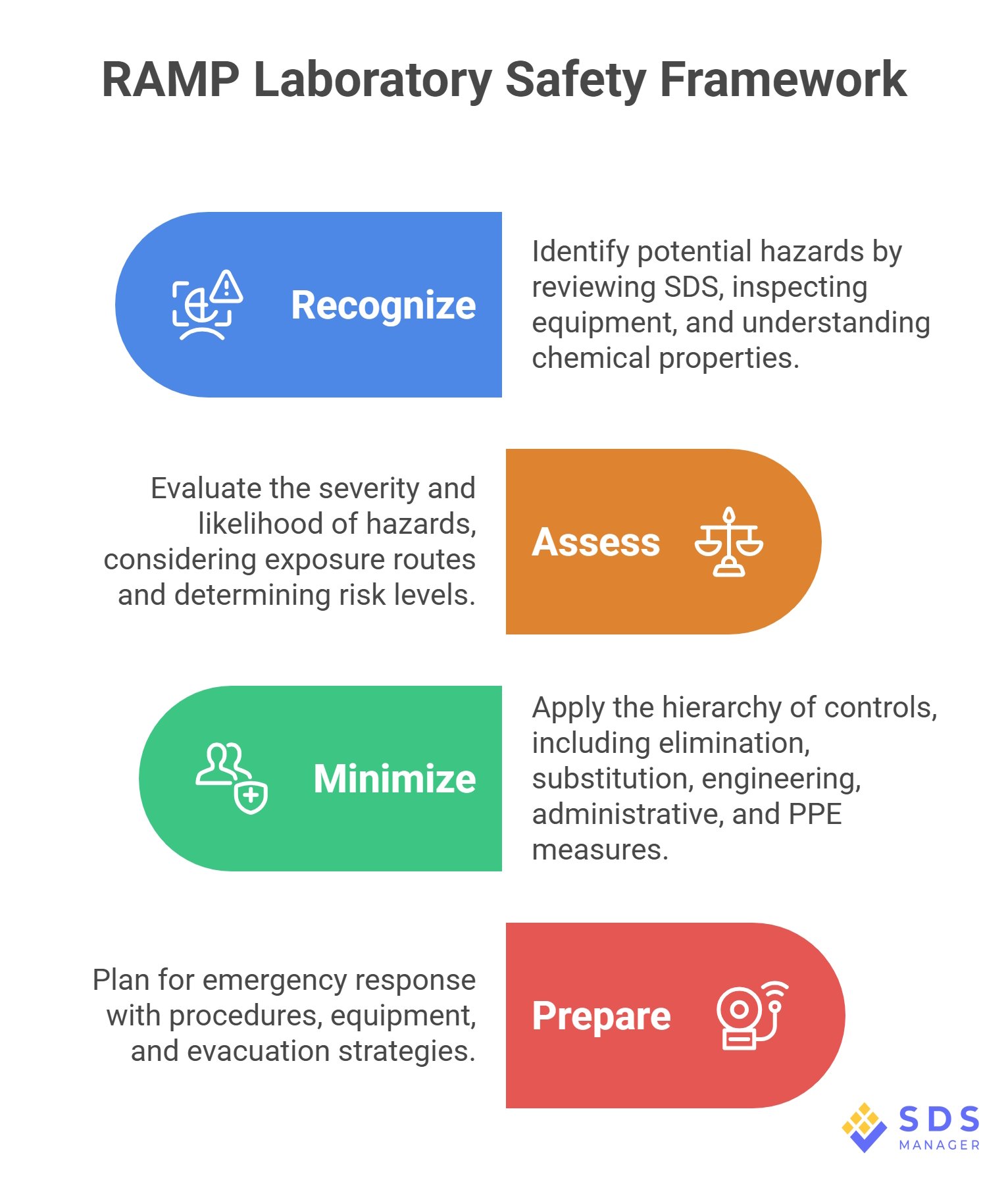

Before beginning the process of handling chemicals, apply RAMP:

2) Ensure hazard communication for every container

Make sure anyone who might use the material can identify it and understand the risks. Use clear labels with names and hazard information on all working and storage containers. Keep SDS easy to access in digital or print form. These help in understanding the hazards and risks associated with each material.

3) Store and handle by compatibility

Avoid storing incompatible chemicals together.

- Keep acids separate from bases

- Store oxidisers away from organics

- Keep water-reactives clear of aqueous substances

Use secondary containment (such as spill trays) for liquids, and follow your lab’s chemical storage plan rather than alphabetised shelving.

4) Use engineering controls correctly

If vapors or aerosols can form while handling a chemical, move the task to a chemical fume cupboard.

- Work at least 6 inches inside the sash

- Raise large apparatus by 2 inches to maintain airflow

- Never store chemicals in the hood

- Close the sash when unattended

5) Be ready for emergencies

In case lab personnel are affected by chemical spills in the eye, first aid involves knowing the route to the eyewash and safety shower.

After a splash, flush with lukewarm water for 15 minutes, then seek medical care and report the incident.

6) Manage waste and housekeeping

- Label chemical waste containers and keep them securely closed

- Avoid mixing incompatible waste streams

- Keep exits and access to emergency gear clear

- Clean work surfaces and log any safety concerns at the end of each shift

Guidelines for the Management of Hazardous Waste sets the rules for waste disposal. For off-site transport, follow NZS 5433.

7) Keep improving with a management system

Build your lab’s routine around a simple safety management cycle. ISO 45001 is a widely used, global framework for finding hazards, setting controls, and reviewing performance.

8) Report serious incidents

Investigate promptly and report hazardous occurrences as required under the Labour Program (for federally regulated employers).

PPE in chemical labs: what each item does and when to use it

PPE is your last line of defense after elimination, substitution, and engineering or administrative controls. Choose PPE based on the chemical, the task, and the exposure route, and verify standards or markings where applicable.

Tip: Glove choice depends on permeation and breakthrough time. Always check the SDS and the glove maker’s chart, not just the material name.

PPE requirements and significance

| PPE item | What it protects you from | When to use it (simple examples) | How to use it correctly | Common mistakes to avoid |

|---|---|---|---|---|

| Safety glasses | Eye impacts, small splashes, and debris | Setting up apparatus, handling sealed containers, weighing powders; general bench tasks with low splash risk | Use side shields or wraparound frames; lenses should be clean and scratch-free; fit so coverage stays over the eyes | Wearing above eyebrows or low on the nose; no side protection; scratched lenses that reduce visibility |

| Splash goggles | Liquid splashes and mists that can reach the eyes; light vapor irritation | Diluting acids or bases, transferring solvents, washing glassware | Ensure a full face seal; indirect vents are recommended for liquid work; strap snug, not tight | Swapping goggles for glasses during wet work; lifting goggles mid-task |

| Face shield (over goggles) | Large splashes, sudden releases, and flying fragments to the face and neck | Large volume transfers, pressurised containers, reactive mixes | Always wear over goggles; shield extends from chin to forehead; ensure full chin-to-forehead coverage | Using a shield instead of goggles for chemicals; cloudy/shabby shields that obscure vision |

| Chemical-resistant gloves (nitrile, neoprene, butyl, etc.) | Skin contact and chemical soak-through from solvents, corrosives, and sensitizers | Handling liquids, cleaning, waste transfer, wiping spills | Choose gloves based on chemical compatibility and replace before breakthrough; change on a schedule; remove inside-out | Choosing only by material name or thickness; wearing past breakthrough time; rinsing disposable gloves with solvents |

| Lab coat | Splashes to the torso and arms; reduced flame spread with FR coats | Everyday benchwork, minor heating, liquid transfer | Fully fasten front; sleeves to wrist; wear flame-resistant cotton near ignition sources | Rolled sleeves; open fronts; synthetic streetwear underneath that can melt |

| Chemical apron | Extra protection to chest and lap against corrosive or high-volume splashes | Acid/base baths, drum transfers, clean-up tasks | Wear over a lab coat; check chemical compatibility of apron material (confirm via SDS/supplier) | Using PVC with strong solvents where it degrades; loose/dangling straps |

| Closed-toe shoes / overshoes | Spills on feet, sharp edges, and broken glass | Any lab activity involving liquids or glass | Wear enclosed, sturdy shoes; use overshoes for high splash risk | Open shoes; mesh/knit or absorbent fabrics in spill areas |

| Respirator (task-specific; last resort) | Breathing in harmful vapors, gases, or aerosols when other controls fall short | When local exhaust isn’t sufficient (e.g., emergency clean-up) | Use only within a written programme; must include fit testing and proper filter selection according to hazard | Wearing one without fit testing; wrong cartridge; relying on a respirator instead of fixing ventilation |

Also know your chemical lab safety equipment locations: eyewash, shower, extinguishers, alarms, spill kit, and gas shut‑offs. Practice reaching them with eyes closed.

Final Thoughts

This checklist guides how regulators and professional bodies expect labs to run:

Clear hazard communication, risk‑based controls and good engineering practice at the bench, trained use of emergency equipment, and PPE chosen by data, not guesswork.

Keep these parts in sync, and your chemical safety rules in laboratory practice will be strong, simple, and repeatable.

FAQs

What is the quickest way to assess risk before an experiment?

Read the SDS, note hazards and exposure routes, then confirm ventilation and PPE match your assessment and training. Keep SDSs accessible to workers.

Why “add acid to water”?

It reduces heat and splash risk during dilution. Do it in a fume cupboard with splash protection, following your SDS.

How do I know which glove to use for a solvent mix?

Use the SDS plus the manufacturer’s permeation chart, then pick an AS/NZS 2161.10.1 / ISO 374-1 type with enough breakthrough time. Replace on schedule.

How long should I rinse if a chemical gets in my eye?

Start flushing immediately and continue for ≥15 minutes; keep eyewash/shower equipment serviceable and close to the hazard

Do safety glasses replace goggles?

No. Glasses are for impact. For liquids, use splash goggles; add a face shield for high splash.

When do I need to notify WorkSafe?

Notify as soon as possible for deaths, notifiable injuries or illnesses, or serious incidents that create immediate risk (for example, a major chemical leak). Preserve the site.