What Has Changed in OSHA Enforcement

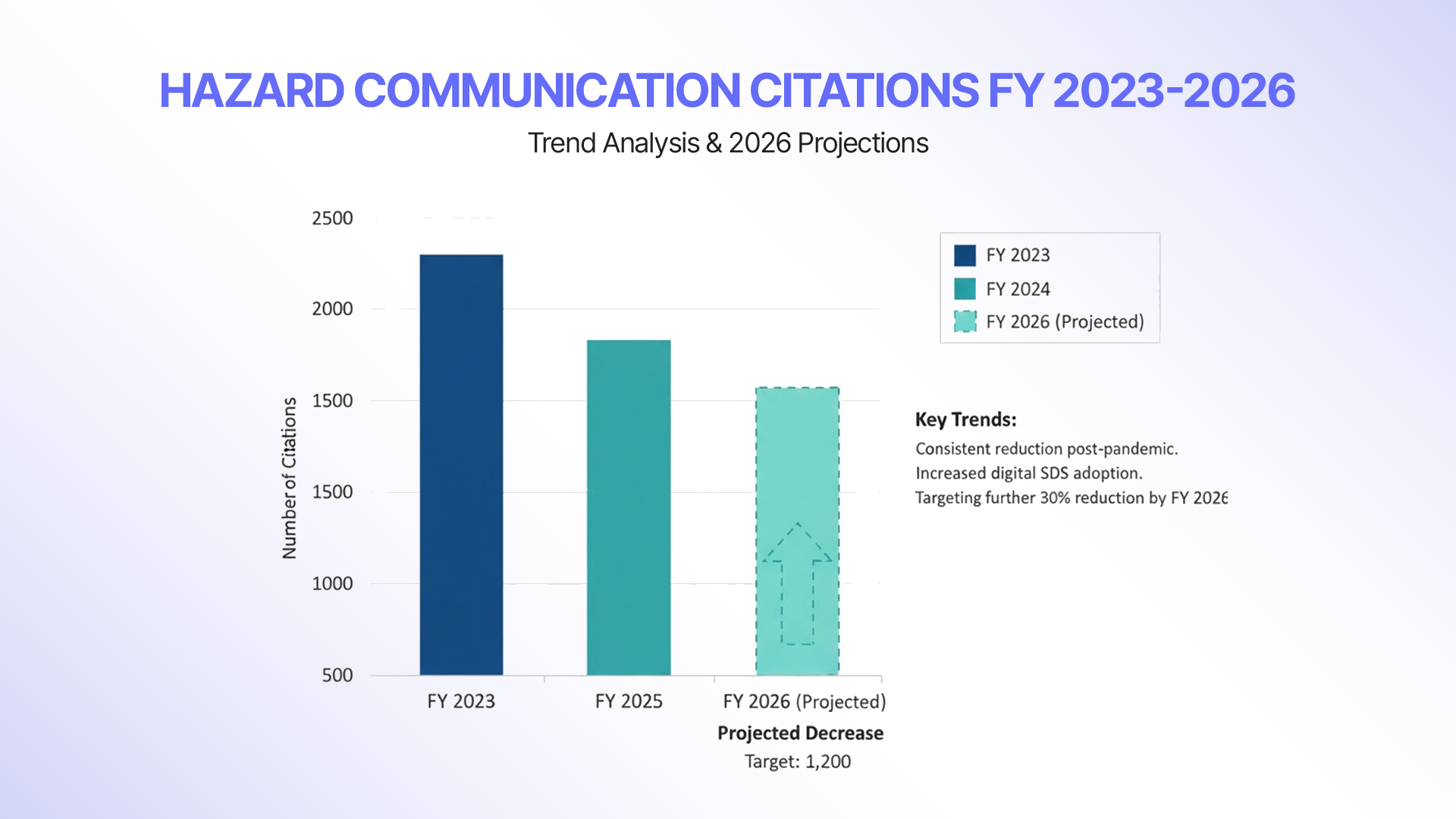

In 2025, OSHA stepped up inspections for chemical hazards and Hazard Communication violations. Proposed penalties increased, and Local Emphasis Programs now cover more high-risk sectors. Publicly released inspection data showed common compliance gaps, helping employers compare their practices. Hazard Communication is still one of OSHA’s most cited standards, showing that having SDSs that are easy to access, current, and properly distributed is key for compliance in 2026.

Source: OSHA Common Statistics and the National Safety Council (NSC).

Common SDS-Related Compliance Issues

Inspections often find gaps that can lead to wider compliance checks. The most common issues are missing or outdated SDSs, limited employee access, inconsistent versions at different sites, and missing training records. Inspectors check not only that SDSs exist but also that employees can use them in daily work.

| Violation Category | Typical Inspection Finding | |

|---|---|---|

| Missing SDSs | Chemicals observed in use without SDS immediately available | |

| Outdated SDSs | SDS revisions missing after hazard or formulation changes | |

| Limited Employee Access | SDSs not accessible to all shifts or at point of use | |

| Inconsistent Information | SDS content contradicts container labels or observed hazards | |

| Lack of Training Documentation | Employees not retrained or informed after SDS updates |

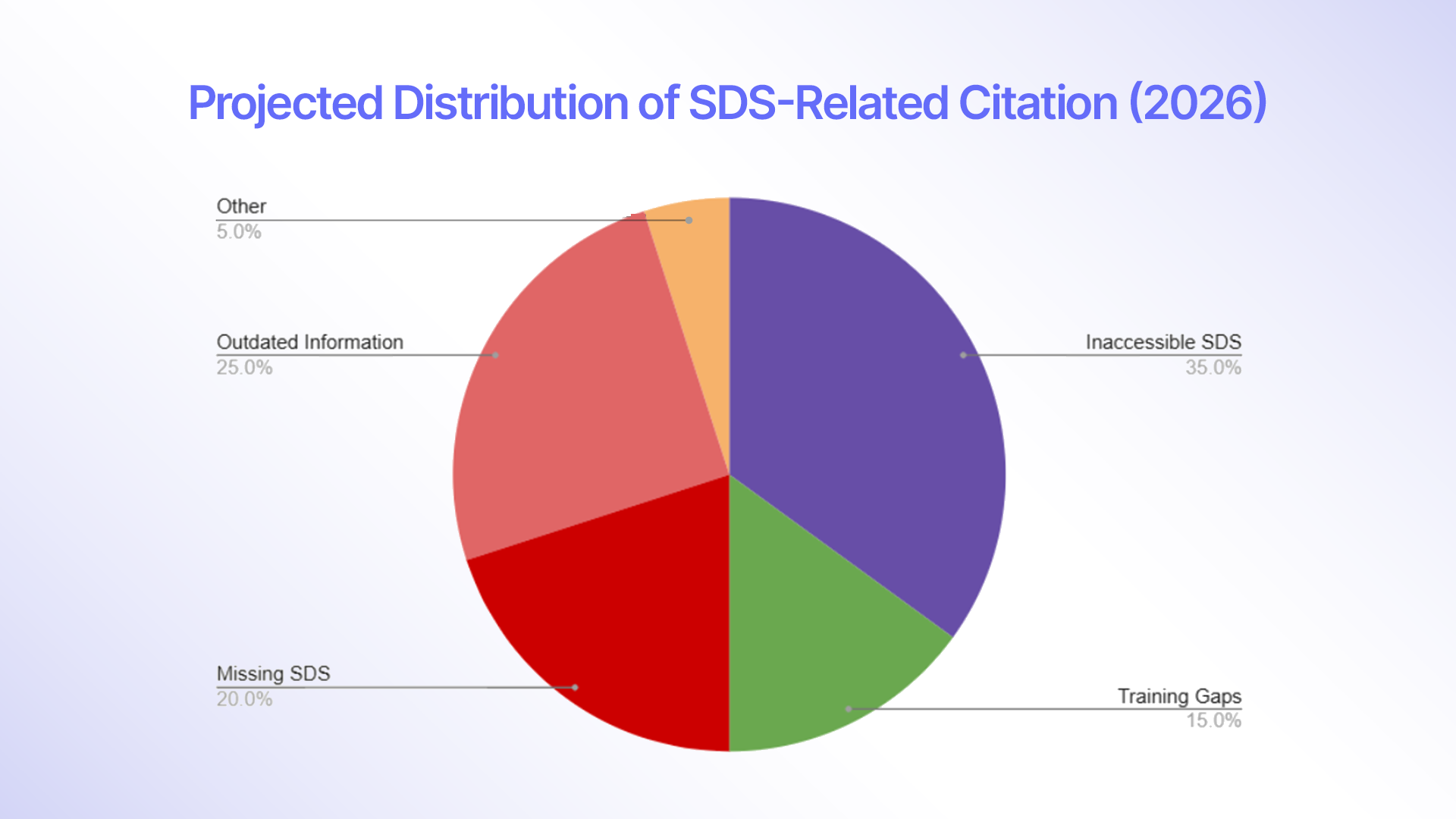

2026 Projected SDS Citation Distribution

The move toward digital compliance is expected to change the way Hazard Communication violations are cited. As regulators focus more on real-time access and accurate data, common violations are likely to shift.

- Accessibility is Key: Even with digital systems, SDSs can still be hard to access, often because of missing backups or login issues.

- Up-to-Date Information: As chemical formulations change, inspectors increasingly expect SDSs to have the most current safety data.

- Training Matters: Having digital tools is not enough; OSHA and other agencies are making sure employees know how to use them to access critical safety information.

Source: OSHA Enforcement Data and analysis from safety compliance experts like J.J. Keller.

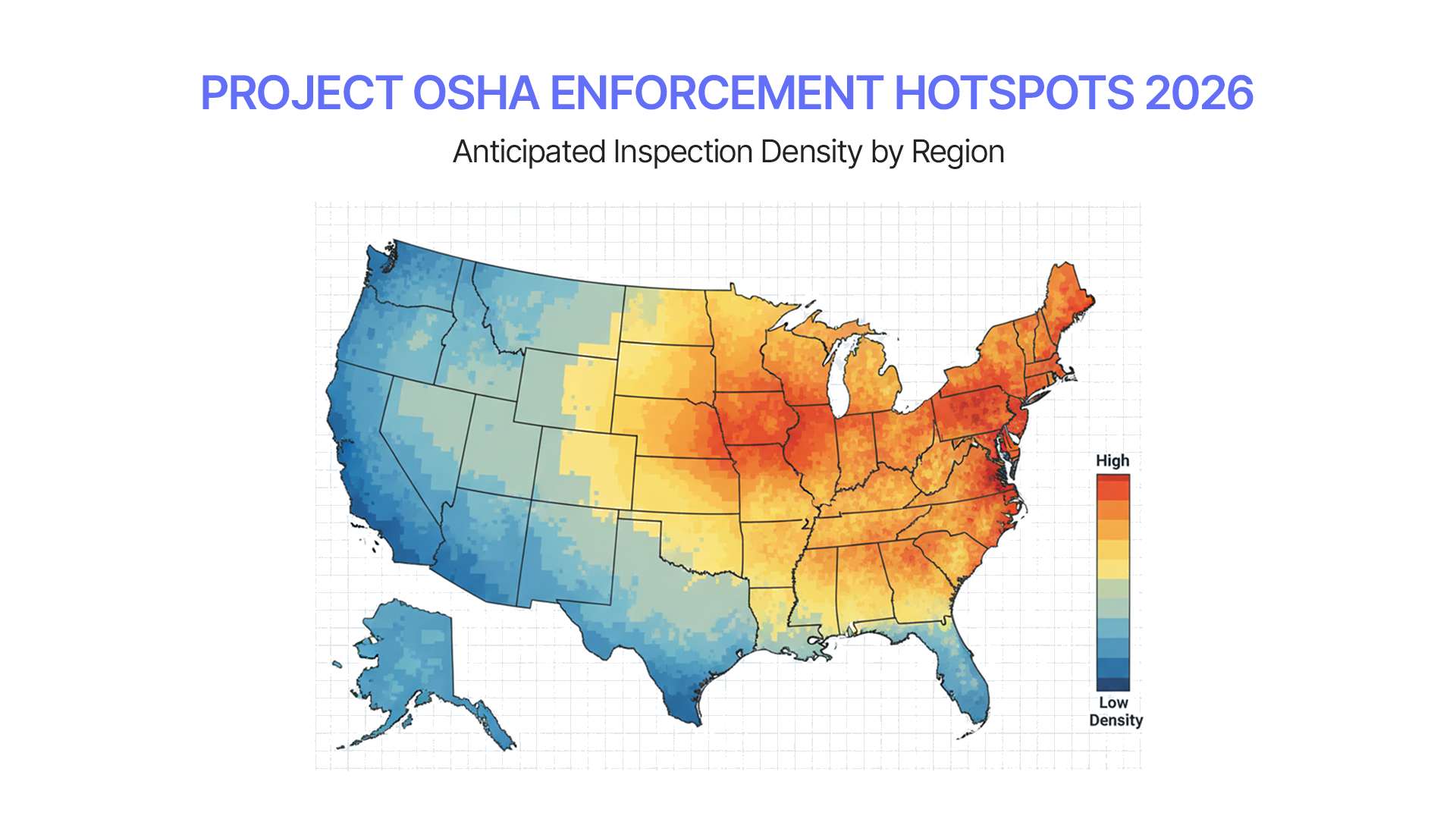

Industries Most Often Affected

Inspection data shows that some sectors face higher enforcement risks. Manufacturing, warehousing, and logistics often run multi-shift operations and manage complex chemical inventories. Construction and multi-employer sites handle a wide range of chemicals, making consistent SDS management difficult. Agriculture, food processing, and healthcare labs also appear often in enforcement reports because of mixed chemicals, specialized reagents, and varying training levels. These industries

Source: U.S. Department of Labor (DOL) Newsroom.

Action Steps for Employers

To meet 2026 compliance expectations, employers should:

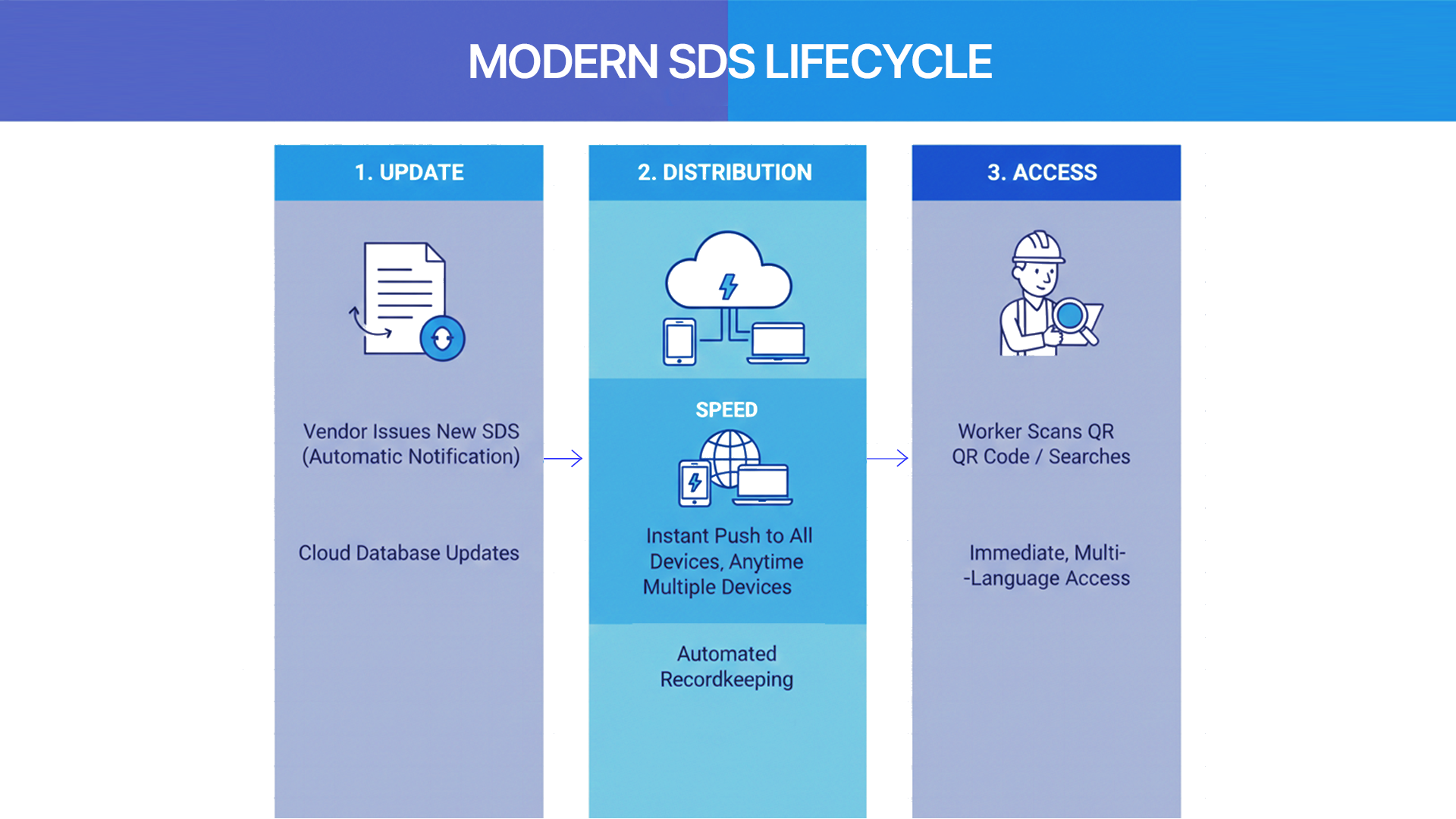

- Update and Check SDSs Quickly – Make sure all hazardous chemicals have current SDSs that reflect actual hazards and workplace conditions.

- Provide Instant Employee Access – SDSs should be available wherever chemicals are used, for all shifts, and in emergencies. Digital tools like SDS Manager offer secure, central access and keep a clear audit trail.

- Keep Records – Track SDS updates, employee notifications, and training. Centralized digital systems automatically log changes, showing a proactive approach to compliance.

Looking Ahead to 2026

OSHA enforcement trends show that Hazard Communication and SDS management will remain a focus. Employers can expect updated citation reports, broader Local Emphasis Programs, and closer checks on accessibility, version control, and documentation. Managing SDSs proactively helps organizations lower inspection risks and keep strong safety practices in 2026.

Key Takeaways

SDS management is a key part of OSHA enforcement risk. Organizations using outdated or scattered methods face higher chances of citations, slower responses, and operational inefficiencies. Using proactive digital SDS management supports smoother inspections, stronger safety practices, and better readiness for chemical emergencies.