As regulations evolve and workplace safety expectations rise, the role of health and safety managers is more critical than ever. One of the foundational pillars of chemical safety is proper management of Safety Data Sheets (SDS). But staying compliant in 2025 isn’t just about collecting documents, it’s about making sure they’re accurate, accessible, and part of a proactive safety culture.

Why SDS Compliance Matters

An SDS is more than just a regulatory document, it’s a critical risk management tool that provides essential information about the hazards of a chemical, how to use it safely, and the appropriate actions to take in an emergency. Under the WHS Regulations and guidance from Safe Work Australia, employers are required to ensure that all hazardous chemicals in the workplace are accompanied by an up-to-date and compliant SDS. Proper management of SDSs helps protect worker health and safety, fulfills an employer’s duty of care obligations, ensures compliance with the Model WHS Laws, and significantly reduces the risk of serious incidents or legal consequences.

That’s why we’ve created the ultimate SDS compliance checklist. If you're responsible for chemical safety at your workplace, this is your roadmap to a safer, more compliant operation.

1. SDS Present for All Chemicals

Every hazardous chemical in your workplace, whether it's in use or in storage, must have an SDS. This is the first and most essential step in compliance. If a product arrives without one, contact the supplier immediately. You can also use our Free SDS search tool to find the SDS you need.

2. SDSs Are Up-To-Date

When a new SDS arrives, always check the revision date to ensure it reflects the most recent version. Regulations and formulations can change, so it’s important to confirm that you're working with the latest information. If the SDS is outdated or doesn’t show a clear revision date, reach out to your supplier for clarification or an updated version. Staying current supports compliance and protects your team.

3. Archived SDS Versions Stored

In Australia, it is essential to keep records of previous Safety Data Sheet (SDS) versions, especially if a chemical product has changed over time or is no longer used on-site. According to Safe Work Australia’s Model Work Health and Safety Regulations, businesses must retain SDSs and related records to demonstrate compliance and support workplace safety.

Safe Work Australia recommends retaining SDSs for a reasonable period (best practice is to store archived SDSs for at least 30 years) to document potential employee exposure to hazardous substances, particularly for substances with long latency periods such as carcinogens. This helps ensure that your organisation can provide evidence during workplace health investigations or audits.

To manage archived SDSs effectively, store them securely either as physical copies or within an SDS management software so they remain accessible when needed for compliance, risk assessments, or incident investigations.

4. Correct Language

Safety Data Sheets (SDSs) must be provided in a language that your employees can understand. In Australian workplaces, this typically means English. However, Australia is home to a diverse workforce, including many Indigenous Australians who may speak traditional languages or English as a second language. Employers have a legal duty under the WHS laws to ensure that safety information and SDSs are clearly communicated and understood by all workers. Ensuring SDSs are accessible in the correct language is not only best practice but a compliance requirement to protect all workers effectively.

5. Digital or Physical Access Provided

SDSs must be easy to access for employees, especially at the point of use. Whether that means having printed copies near workstations or using a QR code system that links to digital files, the key is that workers can find and read the documents without delay. Accessibility is a core part of regulatory compliance.

6. Employee SDS Training Provided

Having SDSs on hand isn’t enough, employees must be trained to understand and use them. That includes recognizing hazard information, following safe handling procedures, and knowing what to do in an emergency. Training should be provided during onboarding, when new chemicals are introduced, and as part of regular safety refreshers.

7.Routine SDS Library Review

A best practice is to review your SDS collection every 6 to 12 months. This ensures that all documents are still up-to-date, and aligned with your chemical inventory. It also helps you identify outdated products or chemicals no longer in use. Regular reviews are one of the simplest ways to stay audit-ready. Be sure to mark the latest review date.

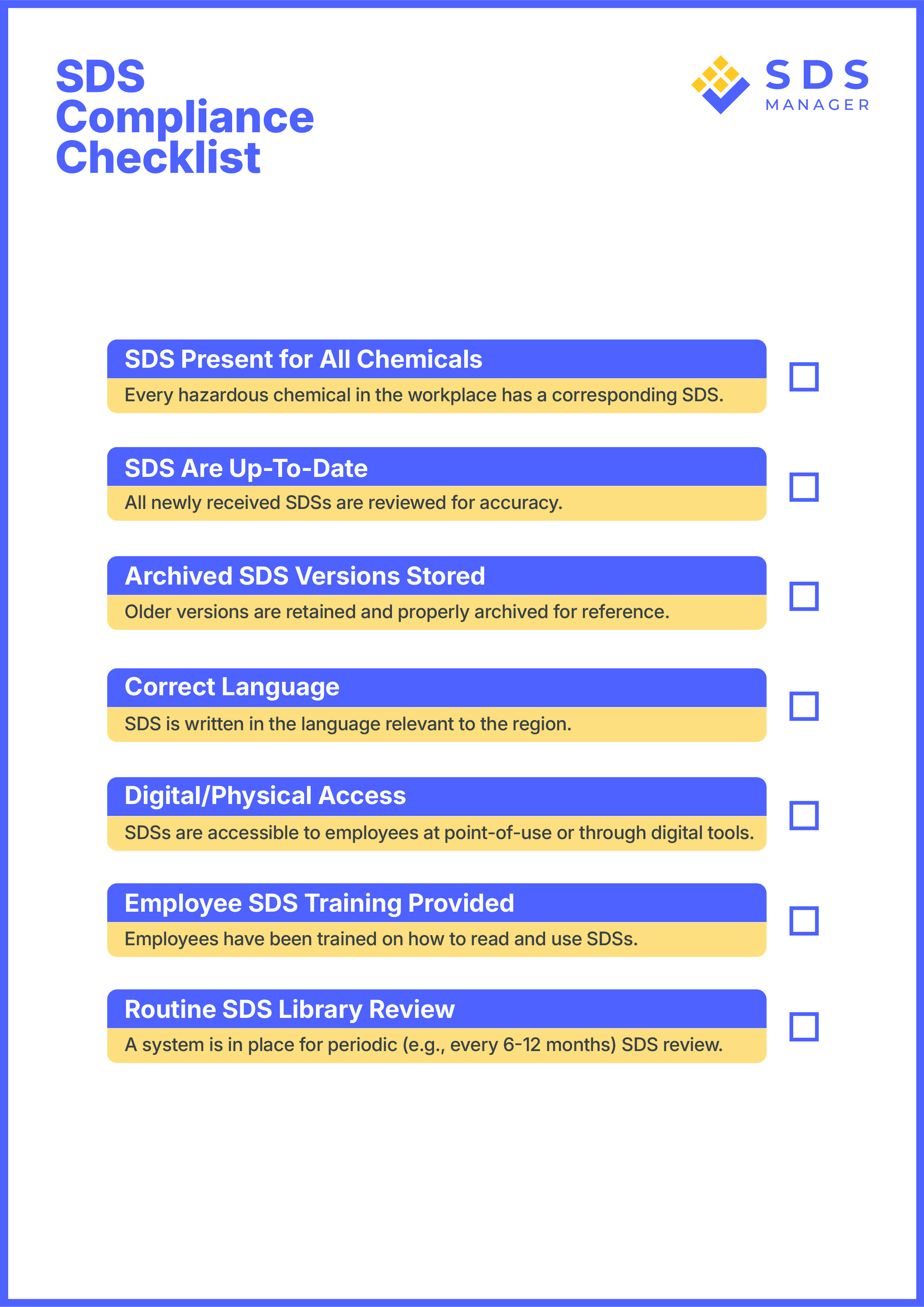

Your Go-To SDS Compliance Checklist

To simplify SDS compliance, we’ve created a comprehensive checklist. Whether you’re updating your chemical safety program or prepping for an audit, this checklist keeps you organized and compliant. Download the image below for quick reference.

Compliance Is Culture

SDS compliance isn’t just about meeting legal requirements, it’s about creating a safer, more reliable workplace where employees feel valued and protected. Keeping your safety data sheets accurate, up to date, and easy to access helps teams respond quickly to spills, choose the right protective gear, and make smart decisions during emergencies. When everyone understands how to use these documents, safety becomes a shared responsibility, not just a management task. A well-managed SDS system shows your commitment to health, safety, and a culture of care.

How SDS Manager Can Help

SDS Manager is designed to help safety managers stay on top of their SDS responsibilities with tools that align closely with the checklist above.

- Multilingual Access & QR Codes: Provide SDSs in multiple languages with instant mobile access via QR codes.

- Automated SDS Updates: Always stay compliant with the latest SDS versions, automatically sourced from manufacturers.

- One click access to safety information: Safety information is instantly accessible, with hazard details, PPE icons, first aid information, precaution against accidental spills and more. Additionally, a Safety Information Summary can be generated to give employees the essential guidance they need when handling chemicals.

- Generate Secondary container labels: Generate secondary container labels in 15 sizes. Labels feature QR codes, crucial H- and P-codes, and PPE icons.

Getting Started Is Easy

Whether you're building your SDS library from scratch or upgrading your current system for better compliance in 2025, SDS Manager makes the process simple and stress-free. Here's how you can take the next step toward streamlined chemical safety:

- Contact Us For Free Setup Support

- Uncover Features Designed With Your Challenges In Mind

- Book A 1:1 Consultation To Discuss Unique Compliance Needs

Take the First Step Toward Smarter SDS Management: Start Your Free Trial Today!