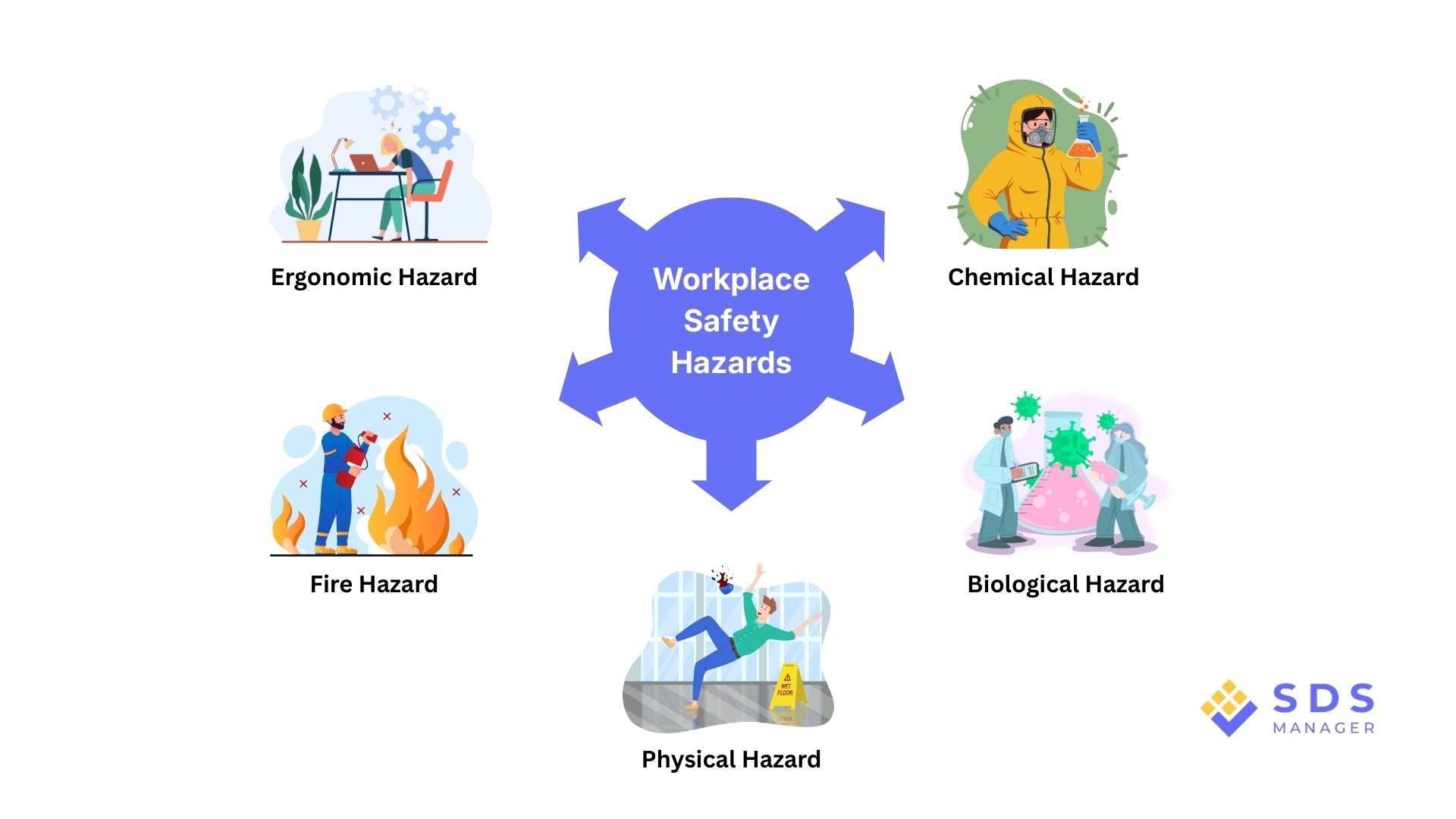

We’ve created a list of 5 common safety hazards that show up no matter the industry. The list rarely changes.

These five safety hazards often follow a predictable pattern. Understanding them can change the way you work and the way you lead others.

Knowing what the 5 safety hazards are that show up again and again doesn’t just protect people. It builds a culture where everyone feels responsible for safety.

Let’s take a closer look at the list of safety hazards in this article.

What Are the 5 Types of Safety Hazards?

1. Chemical Hazard

Chemical risks exist in every workplace, from cleaning supplies to industrial solvents. If you’re wondering which safety hazard you should focus on first, chemical hazards always rise to the top.

These risks often stem from unlabeled containers, incompatible storage, poor ventilation, spills, and everyday materials that carry hidden dangers.

Chemical exposure can cause burns, breathing difficulties, long-term health issues, or sudden injury, and many incidents occur because employees didn’t have the information they needed at the moment they needed it.

Strong SDS management changes that. Instant access to safety data sheets gives employees clear guidance on handling, first-aid steps, emergency actions, and PPE requirements.

This in turn helps mitigate chemical safety hazards and keeps people safe.

2. Biological Hazard

Biological hazards show up in everyday workplaces far more than people realize. These hazards come from things like bacteria, viruses, mold, and other microorganisms that can make people sick, trigger allergies, or cause infections. Managing these hazards means having clear, practical safety steps in place.

Workers need to know how to handle materials safely and how to clean and disinfect properly. Regular training helps people understand why handwashing, good housekeeping, and proper waste disposal matter. Routine inspections, quick reporting of problems, and updates to procedures keep the system working.

Understanding the specific sources of biological hazards makes prevention easier. Identifying how a hazard spreads, whether through breathing it in, touching it, or eating contaminated items, helps guide the right controls.

3. Physical Hazard

Physical hazards are risks that come from the environment itself. It includes things like noise, vibration, extreme temperatures, moving machinery, sharp edges, poor lighting and more.

These hazards often come from everyday conditions such as loud equipment, machines without guards, cluttered walkways, slippery floors, hot surfaces, cold storage areas, or work spaces that are too dark. Because they’re so common, people sometimes stop noticing them, which increases the risk of injury.

Prevention starts with good housekeeping, proper machine guarding, enough lighting, and regular equipment checks. Using the right PPE, controlling noise levels, and keeping walkways clear also make a big difference. When workers stay aware of their surroundings and speak up when something looks unsafe, physical hazards are much easier to control.

4. Fire Hazard

Fire hazards are risks that can lead to ignition, smoke, or explosions, and they exist in almost every workplace.

They often come from flammable materials, heat sources, poor storage practices, or equipment that isn’t maintained properly. Even electrical hazards, like overloaded outlets or damaged cords, can spark fires when left unaddressed.

Preventing fire hazards starts with proper storage of flammables, keeping escape routes clear, maintaining equipment, and training workers to recognize high-risk conditions. Every workplace should train their employees in fire safety drills so they know what to do in case a fire breaks out.

Regular inspections, working smoke detectors, clean work areas, and easy access to fire extinguishers all help stop fires before they start.

5. Ergonomic Hazard

Ergonomic hazards are risks that come from how work tasks interact with the human body. They develop when workers repeat the same motions, lift improperly, sit or stand in awkward positions, or work at stations that aren’t designed to fit their movements.

These hazards often come from repetitive tasks, poor workstation setup, heavy manual lifting, tools that require awkward hand positions, or long hours spent typing, bending, or reaching. Because the strain builds slowly, people usually don’t notice the damage until pain becomes constant.

Prevention focuses on adjusting workstations, improving posture, rotating tasks, using ergonomic tools, and teaching proper lifting techniques. Small changes, like raising a monitor or using supportive seating, make a big difference. When workers are comfortable and supported, they stay safer and more productive.

Final Thoughts

Understanding the 5 safety hazards that repeat across workplaces helps build a stronger safety culture. These hazards are predictable, and because they’re predictable, they’re manageable.

Awareness leads to action. When people understand these five safety hazards that shape their daily environment, safety stops feeling like a rulebook and starts becoming a shared value.

Small, consistent improvements create safer workplaces. And safer workplaces create stronger, more confident teams ready for the future.