In Canada, chemical labelling requirements are governed by WHMIS 2015 (Workplace Hazardous Materials Information System), which aligns with the Globally Harmonized System (GHS) and is enforced under the Hazardous Products Act (HPA) and Hazardous Products Regulations (HPR).

Labels are an important part of hazard communication, they provide critical information to protect workers from chemical exposure risks. Understanding the difference between primary and secondary container labels is key to staying compliant with WHMIS 2015 and maintaining a safe workplace.

What Is a Primary Container Label?

A primary container label is the original label provided by the manufacturer, importer, or distributor on the container in which the chemical is shipped.

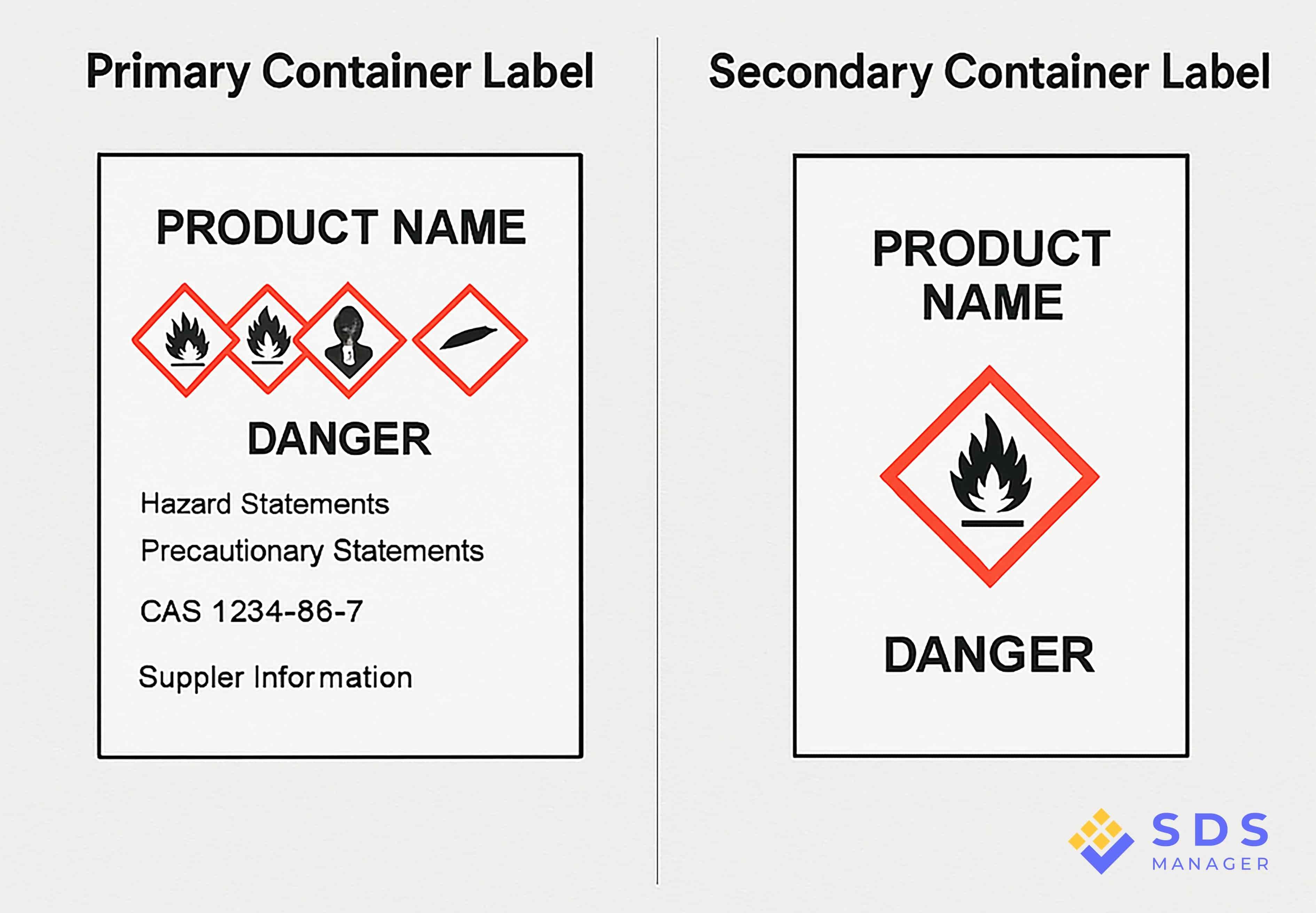

WHMIS 2015 Requirements for Primary Labels: Must include all GHS label elements.

- Product identifier – Matches the name in the Safety Data Sheet (SDS)

- Supplier information – Name, address, and phone number of the responsible party

- GHS pictograms – For all applicable hazard classes

- Signal word – “Danger” or “Warning”

- Hazard statements – Standardized descriptions of hazard types and severity

- Precautionary statements – Guidance on safe handling, storage, and disposal.

- Supplemental information – If required under the HPR.

Example: A gallon of paint thinner shipped from the manufacturer with a label containing the flammable pictogram, “Danger” signal word, and hazard/precautionary statements.

What Is a Secondary Container Label?

A secondary container label is used when a chemical is transferred from its primary container into another container for use within the workplace.

When Required Under WHMIS 2015

Every workplace container holding a hazardous product must be labelled unless:

- It is used immediately by the worker who transferred it, and

- It remains under their direct control the entire time.

If the product is left unattended, shared with coworkers, stored for later use, or moved outside the immediate work area, it must have a compliant workplace label.

Minimum Requirements for Secondary Labels

At a minimum, secondary container labels should include:

- Product identifier – Consistent with the SDS.

- Hazard information – Words, symbols, or pictograms giving general hazard awareness.

Best practice (recommended by the Canadian Centre for Occupational Health and Safety – CCOHS): Add signal words, hazard statements, and pictograms for greater clarity and consistency.

Key Differences Between Primary and Secondary Labels

| Differences | Primary Container Label | Secondary Container Label |

|---|---|---|

| Created and Applied By | Manufacturer, importer, or distributor | Employer or workplace staff transferring the chemical |

| Content | Full WHMIS 2015 supplier label (product ID, supplier info, pictograms, hazard & precautionary statements) | Minimum: product ID + hazard information; Recommended: pictograms, signal words, hazard statements |

| Purpose | Communicate full hazard and regulatory information to any handler | Communicate hazards to employees in the workplace |

| When Required | On all hazardous products sold or imported into Canada | On all workplace containers not used immediately by the person who filled them |

| Regulatory Basis | Hazardous Products Act (HPA) & Hazardous Products Regulations (HPR) under WHMIS 2015 | WHMIS 2015 workplace labelling requirements |

Common Workplace Compliance Mistakes

- Leaving secondary containers unlabeled when shared or stored for later use

- Using abbreviations or chemical codes that employees can’t understand

- Not matching the product name to the SDS exactly

- Failing to update labels when chemical formulations or hazards change

The Easy Way to Stay Compliant

Manual creation of compliant secondary labels can be slow and error-prone. SDS Manager’s free GHS Secondary Label Generator allows you to:

- Auto-fill hazard information directly from your SDS

- Support multiple label sizes and layouts

- Add GHS pictograms and hazard statements automatically

- Include QR codes linking directly to the SDS for instant access

With automation, you can maintain compliance, save time, and reduce labeling errors across your workplace.

Frequently Asked Questions (FAQs)

Q. What is the main difference between primary and secondary container labels?

A: Primary labels are provided by the manufacturer and include full GHS information; secondary labels are applied in the workplace when chemicals are transferred into another container.

Q. Do all secondary containers need a label?

A: No. If the container is used immediately by the person who filled it and never leaves their control, labeling is not required. Otherwise, it must be labeled.

Q. Can I handwrite secondary container labels?

A: Yes, as long as they are legible, durable, and include required hazard information.

Q. Do secondary labels need pictograms?

A: While not always legally required, WHMIS 2015 recommends including them for clarity and safety.

Q. How can I make sure my labels are WHMIS-compliant?

A: Always check the product’s SDS, ensure the workplace label contains the required elements, and follow CCOHS and HSE Canada guidance.