Under WHMIS and the Hazardous Products Regulations (HPR), labels and symbols present hazards in a consistent way so workers and contractors can understand them at a glance.

A label's design consists of a signal word, a pictogram, and specific text detailing both the hazards involved and the necessary precautions to take.

The same information appears in Safety Data Sheets (SDS). Standardized chemical safety signs and symbols keep messaging aligned across labels, postings, and procedures.

Standards that are Applicable and How They are Integrated

| Standard / Authority | Scope | Where it applies | What it standardizes | Notes on integration |

|---|---|---|---|---|

| WHMIS / HPR (Health Canada) | GHS-aligned classification, labels, and SDS | On containers, supplier/workplace labels, and in training | Label elements (signal word, pictograms, hazard/precautionary statements); SDS format | Forms the core content workers read; supplier labels are bilingual (English and French) |

| Facility safety sign systems (ISO 7010 family) | Symbols, colours, shapes for signs | Fixed signage in rooms, corridors, equipment areas, exits | Standard symbols, colour codes, and layouts | Complements WHMIS by creating consistent on-site recognition |

| TDG Regulations (Transport Canada) | Transport identification and response | Loading bays, external doors, vehicles and bulk containers | Placards, labels, UN numbers; display rules and classes | Works alongside WHMIS; informs responders and shipping during transport |

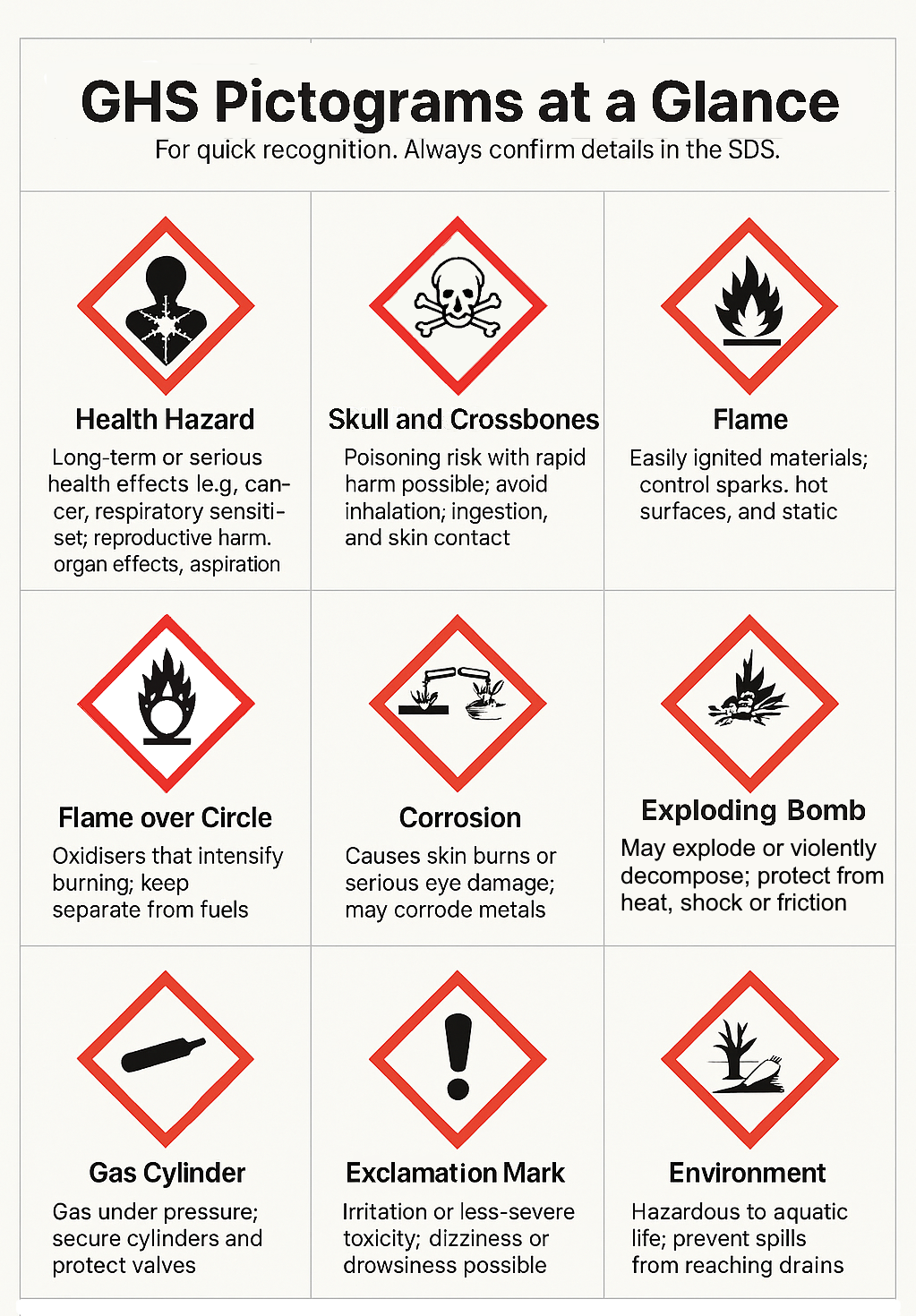

GHS Pictograms and Meanings

This section depicts what GHS pictograms look like and what they mean. There are 9 in total, each assigned to a specific type of hazard.

How to Interpret the TDG Placards and UN Numbers

At transport interfaces and external loading areas, responders rely on TDG placards, labels, and UN numbers.

Placards identify the hazard class and, where required, display the UN number; display rules cover when numbers are shown and how subsidiary classes appear.

Site arrangements and emergency plans generally reflect these markings so shipping and security staff can provide immediate details to responders.

Signal Words, Colours, and Layout Requirements

The signal word should match the product’s WHMIS classification, and standardized colours and layouts are followed so messages remain clear.

- “Danger” indicates immediate, serious hazards

- “Warning” indicates significant but less immediate hazards

- “Caution” marks potential hazards or unsafe practices.

For facility signs, ISO-style symbols and colours support quick recognition across corridors, rooms, and exits.

Where Chemical Safety Signs and Labels Must Be Placed

Primary containers come fully labeled from the supplier, under the HPR and these labels should be kept intact; supplier labels are presented in both official languages.

When a product is poured into a secondary container and will be used later or left unattended, a workplace label that reflects the SDS should be applied.

- In active work areas, warning signs should be placed at critical decision points, such as entrances, exits, and equipment controls, and must be taken down as soon as the risk is eliminated.

- In laboratories, lab safety and chemical hazard signs are placed near eyewash stations, storage cabinets, and entry doors so key information is visible before work begins.

Training and Competency Development

The best way to develop your team's safety skills is with brief and frequent training updates. A proven method is:

- Recognize the Symbol: Know what the safety icon means at a glance.

- State the Risk: Clearly describe the potential hazard.

- Apply the Control: Confidently use the correct safety measure, such as wearing protective equipment, ensuring good airflow, or using a shut-off valve.

You can easily find ready-to-use visuals and handouts from official safety organizations to support your training.

Selecting Appropriate Signage for Your Facility

- In handling areas, WHMIS/HPR label elements that reflect the SDS are expected.

- For loading bays, stores, and external doors, TDG placards and UN numbers are commonly present so responders can assess risk before entry or transport.

- For general warnings and routes, ISO-style symbols and layouts support consistency across the site.

Vendor and authority guides can assist in translating SDS details into the appropriate mix of labels and area signs.

Common Compliance Mistakes

Teams often run into some common issues like:

- Missing labels on secondary containers after a transfer

- Choosing the wrong signal word

- Using non-standard colours or layouts that make labels harder to read.

WHMIS and the Hazardous Products Regulations (HPR) set what the label must include, while ISO-style sign systems guide how facility signs should look and where they should be placed

Final Thoughts

Chemical safety signs function as a shared language. WHMIS/HPR label elements on containers, ISO-style formats on area signs, and TDG markings at transport points together create a consistent system. Keeping labels current, delivering brief refreshers, and maintaining easy access to the SDS help people make better decisions and work safely every day.

FAQs

1) How do WHMIS pictograms differ from TDG placards?

WHMIS pictograms show the type of hazard on container labels and SDSs. TDG placards and UN numbers support transport and emergency response at doors, loading bays, and on vehicles. Both may be present when relevant.

2) Do secondary containers need labels?

Yes. If a product is transferred, a workplace label should be applied before use or if the container will be left unattended. Wording should reflect the SDS.

3) Which signal word should be selected?

To maintain consistency between what is taught in training and what appears on labels, always consult the SDS. It defines “Danger” as the signal word for a higher-level hazard compared to “Warning.”

4) Where should general hazard signs appear in a plant?

Decision points such as entrances, process controls, and exit routes are typical locations. Signs remain visible while the hazard exists.

5) Are official pictogram files available for printing?

Yes. Official, scalable artwork is recommended so symbols remain accurate and readable at any size; ISO-style symbols are applied for facility signage.