SDS Manager allows you to create risk assessments of chemicals and use these for generating Chemical Instructions. These risk assessments must be tailored to your specific use of each chemical, such as the form, quantity, and frequency of use.

We are often asked if SDS Manager offers ready-made risk assessments. The short answer is no - and for good reason. Chemical risk cannot be assessed generically. For example, a small container of gasoline may pose little risk, but storing 1,000 gallons does. If universal assessments were possible, they would already be included in the Safety Data Sheets.

Offering "off-the-shelf" risk assessments is often a sign of poor understanding of chemical safety. SDS Manager ensures that your assessments are context-specific, enabling accurate Chemical Instructions and compliance with safety regulations.

The base information of a risk assessment includes:

-

The form of the substance

-

What the substance is used for

-

How the substance should be used

-

How the substance should be disposed of

-

Duration of exposure to the substance when handled

-

Amount of the substance when handled

-

Hazard types relevant for handling the substance

-

classification of risk, classification of exposure and effect of PPE and controls for each hazard type

-

Storage risk regarding safety events

-

Storage risk regarding environmental release events

For all locations you have the substance stored, you can evaluate the storage risk.

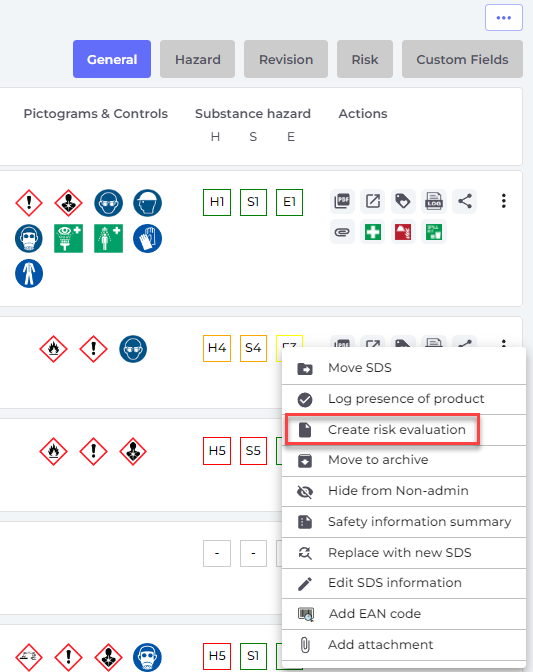

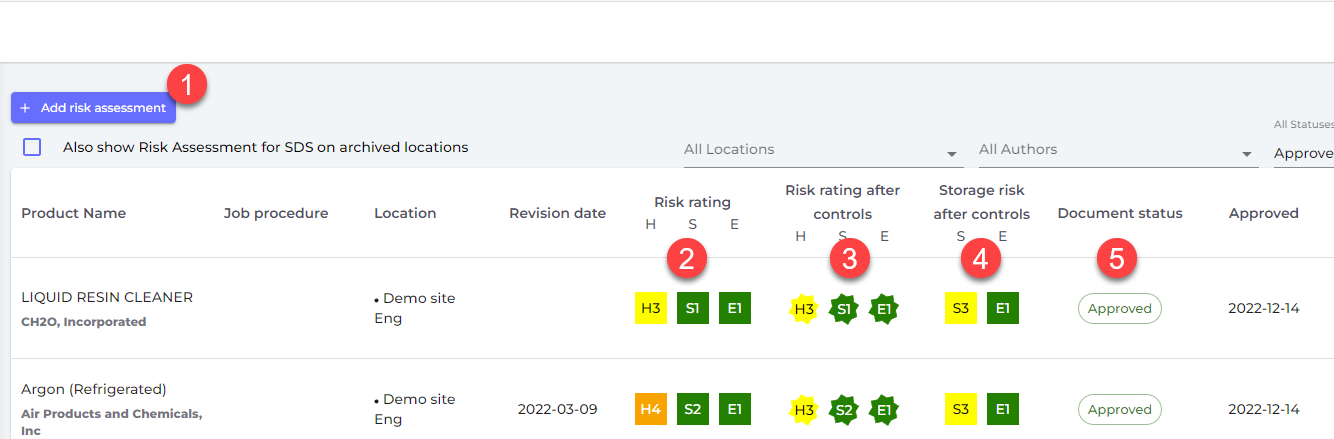

To create Risk assessments for SDS, you will need the PRO version. On the page for Risk Assessments (require login) click the“Add risk assessment” button or select "Create Risk Assessment" from the SDS list.

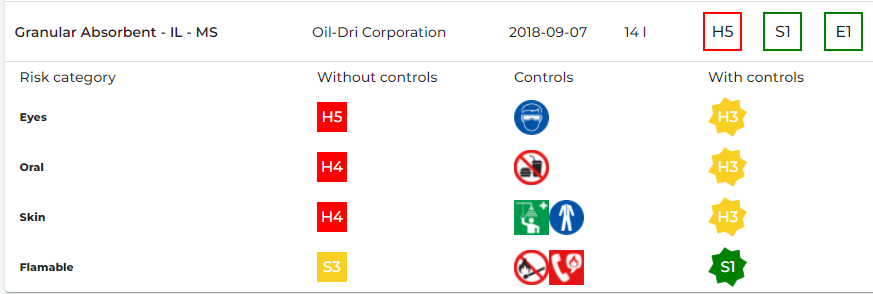

As seen in the below example, SDS Manager allow you document the risk of the chemical when no controls are in place (2).

As part of the risk assessment, you can document required PPE and other controls required for safe handling, storage and disposal of the product. You can also determine the level of risk in handling and storing the chemical when used according to procedures and precautions documented in the risk assessment – i.e. risk rating after controls (3).

Storage risk is determined based on the quantity stored, the inherent safety dangers of the chemicals and estimated likelihood of an safety event where controls are required and document in the risk assessment are in place (4).

SDS Manager allows risk assessments to be approved (5) and when changes are needed, new revisions can be created.

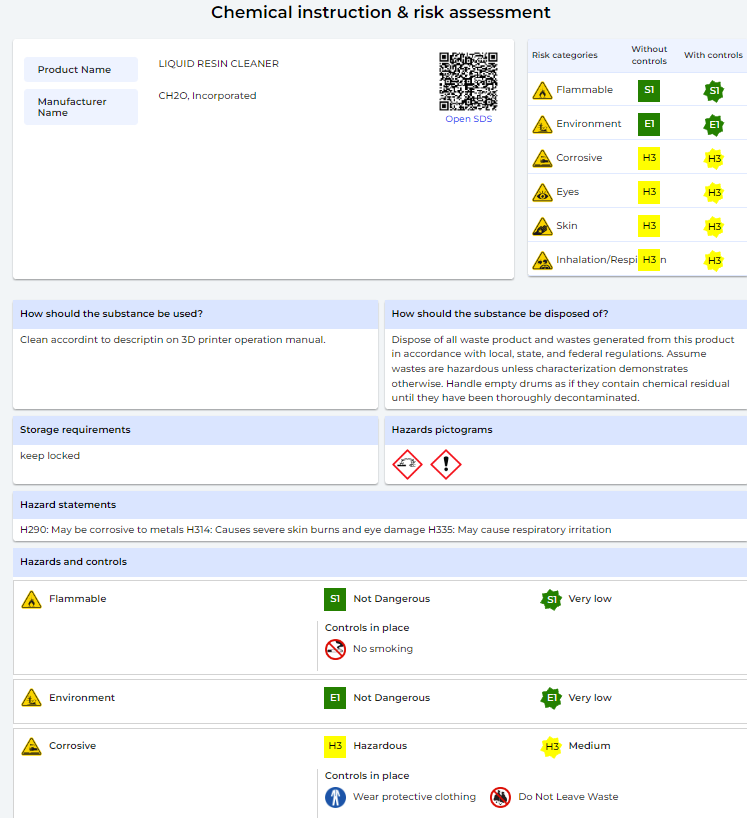

Below is an example of a chemical risk assessment created in SDS Manager:

SDS Manager supports automated generation of secondary container labels.

For chemicals that have been risk assessed, each label will include a QR code that links directly to the corresponding work instruction. Employees can easily access safe handling guidelines by simply scanning the QR code with their phone.

You can try it yourself by scanning the sample QR code on the label below.

Please note: the instructions shown in this example are fictional and should not be used as actual safety guidance.

See example reports:

Below is example of Job work instruction (COSHH report) for work involving the two above chemicals.

Job hazard analysis report - Priming epoxy floor (Click to see PDF file)